| GENERAL |

|

|

| Build Volume (W × D × H) |

Single Extruder Print: 300 × 300 × 300 mm (11.8 × 11.8 × 11.8 inch) |

Dual Extruder Print: 255 × 300 × 300 mm (10 × 11.8 × 11.8 inch) |

| * Individual/single parts sizes are subject to certain limitations, for details, please refer to BASF’s Design Guidelines.

(https://forward-am.com/material-portfolio/ultrafuse-filaments-for-fused-filaments-fabrication-fff/metal-filaments/ultrafuse-316l/) |

|

|

| Machine Size (W × D × H) |

620 × 626 × 1390 mm (24.4 × 24.6 × 54.7 inch) |

|

| Net Weight |

80.55 kg (177.58 lbs) |

|

| Print Technology |

Fused Filament Fabrication (FFF) |

|

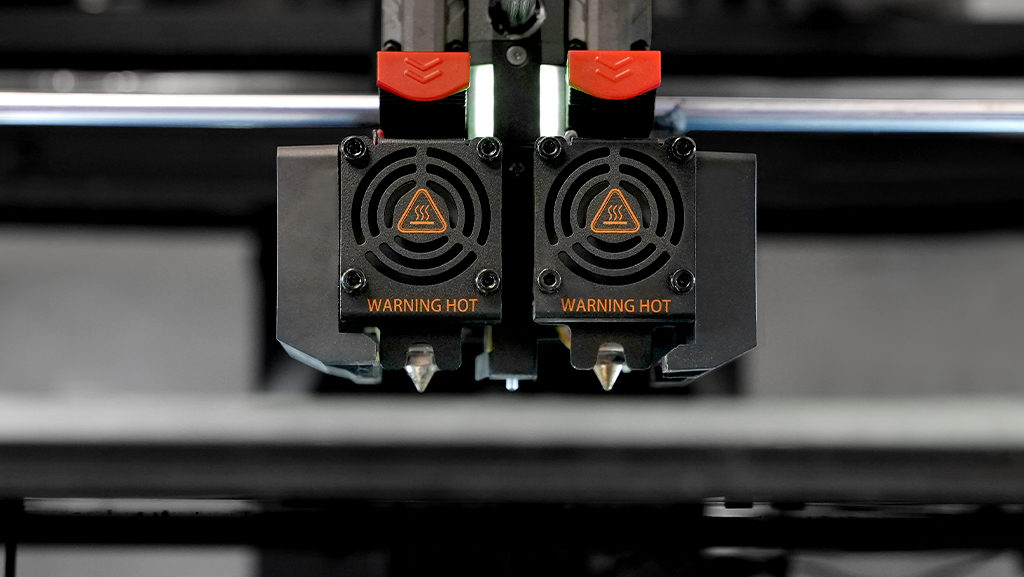

| Print Head System |

Dual-head with electronic lifting system |

|

| Filament Diameter |

1.75 mm |

|

| XYZ Step Size |

0.078125 micron |

|

| Print Head Travel Speed |

30–150 mm/s |

|

| Build Plate |

Glass Build Plate |

|

| Max Build Plate Temperature |

120ºC |

|

| Heated Bed Material |

Silicone |

|

| Build Plate Leveling |

Auto-Leveling |

|

| Nozzle Diameter |

0.4 mm (Default), 0.2/0.6 mm (Available) |

|

| Max Nozzle Temperature |

300ºC |

|

| Connectivity |

Wi-Fi, LAN, USB port, Live camera |

|

| Noise Emission (Acoustic) |

<55 dB(A) when building |

|

| Operating Ambient Temperature |

15-30ºC, 10-65% RH non-condensing |

|

| Storage Temperature |

-25℃ to +55℃, 10-65% RH non-condensing |

|

| ELECTRICAL |

|

|

| ELECTRICAL |

|

|

| Power Supply Input |

100-240 V AC, 50-60 Hz 230 V @ 3.3 A |

|

| Power Supply Output |

24 V DC, 600 W |

|

| MATERIAL |

|

|

| Material Type |

Metals (Ultrafuse® 316L, Ultrafuse® 17-4PH)¹

Support layer material: aluminum oxide (Ultrafuse® Support Layer)²

Note: 1. Metal materials are used to print parts and supports.

2. The support layer material can’t be printed on its own and is only used for layer isolation, allowing for good separation between the support and the prints after sintering.

This product is intended exclusively for sales, distribution, and use within the European Union, Albania, Iceland, Liechtenstein, Monaco, North Macedonia, Norway, San Marino, Serbia, Switzerland, Turkey, and the United Kingdom, and is only available for customers located in those countries. |

|

| SOFTWARE |

|

|

| Slicing Software |

ideaMaker for Metal |

|

| Supported OS |

WINDOWS |

|

| PRINTER CONTROLLER |

|

|

| Onboard Control |

7-inch touchscreen display |

|

| Network Connectivity |

WLAN and Ethernet |

|

| Power Loss Recovery |

Second generation version, built into hardware, batteries not necessary |

|

| Screen Resolution |

1024× 600 px |

|

| Motion Controller |

Atmel ARM Cortex-M4 120 MHz FPU |

|

| Logic Controller |

NXP ARM Cortex-A9 Quad 1 GHz |

|

| Memory |

1 GB |

|