TECHNICAL SPECIFICATIONS

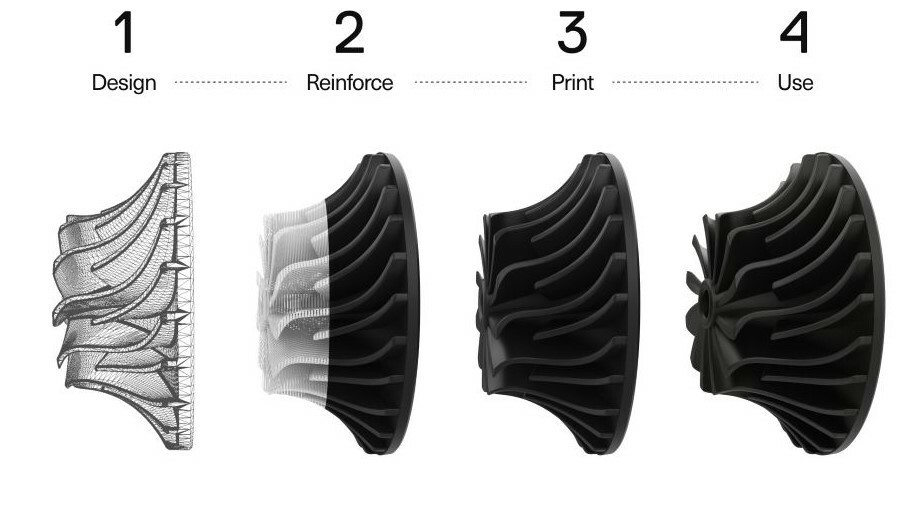

| Printer Properties | Process | Fused filament fabrication, Continuous Filament Fabrication |

| Build Volume | 320 x 132 x 154 mm (12.6 x 5.2 x 6 in) | |

| Weight | 16 kg (35 lbs) | |

| Machine Footprint | 584 x 330 x 355 mm (23 x 13 x 14 in) | |

| Print Bed | Kinematic coupling — flat to within 160 μm | |

| Extrusion System | Second-generation extruder, out-of-plastic detection | |

| Power | 100–240 VAC, 150 W (2 A peak) | |

| RF Module | Operating Band 2.4 GHz Wi-Fi Standards 802.11 b/g/n | |

| Materials | ||

| Plastics Available | Onyx, Precise PLA, Smooth TPU | |

| Fibers Available | Fiberglass | |

| Tensile Strength | 590 MPa (19.0x ABS, 1.9x 6061-T6 Aluminum) * | |

| Tensile Modulus | 21 GPa (9.4x ABS, 0.3x 6061-T6 Aluminum) * | |

| Part Properties | Layer Height | 100 μm default, 200 μm maximum |

| Infill | Closed cell infill: multiple geometries available | |

| Software | Supplied Software | Eiger Cloud (Other options available at cost) |

| Security | Two-factor authentication, org admin access, single sign-on |