What is Stereolithography (SLA)? Understanding the Basics of Resin 3D Printing

Stereolithography, commonly known as SLA, offers unique advantages that make it a go-to choice for a variety of applications, from intricate jewelry pieces to functional prototypes. If you’re curious about what SLA is and how it works, you’re in the right place. With that, let’s explore the basics of resin 3D printing and the world of Stereolithography.

On This Page

- What is Stereolithography (SLA)?

- How Does SLA 3D Printing Work?

- Key Components of an SLA Printer

- Advantages of SLA Resin 3D Printing

- Challenges of SLA 3D Printing

- Applications of SLA 3D Printing

What is Stereolithography (SLA)?

Stereolithography is a 3D printing method that utilizes a process known as resin photopolymerization. This method involves curing liquid resin into solid layers using an ultraviolet (UV) light source. Each layer is cured individually, building up the final 3D object layer by layer. Simply put, it utilizes light to create highly detailed objects from liquid resin. This precision makes SLA particularly well-suited for creating detailed and complex designs.

Related: What are the Different Types of 3D Printing Methods?

How Does SLA 3D Printing Work?

1. Digital Design

The process begins with a digital design created in CAD software. This model serves as the blueprint for the 3D object.

2. Slicing the Model

The digital model is then sliced into thin layers using slicing software. These layers are the instructions that guide the 3D printer.

3. Printing the Object

In SLA printing, a UV laser or projector is used to cure the resin. The build platform dips into a vat of liquid resin, where the laser or projector solidifies each layer according to the digital model.

4. Post-Processing

After printing, objects typically require cleaning to remove excess resin and additional curing under UV light to harden the print.

Key Components of an SLA Printer

- Light Source: A UV laser or projector cures the resin.

- Build Platform: This platform moves incrementally to build each layer of the object.

- Resin Vat: Holds the liquid resin used in the printing process.

- Support Structures: These are used to support overhangs and complex shapes during printing.

Advantages of SLA Resin 3D Printing

SLA 3D printing offers several benefits that make it a popular choice, including:

1. High Precision and Detail

SLA printers are renowned for their ability to produce intricate designs with fine details, making them ideal for applications where aesthetic quality is paramount, such as in jewelry or dental models. Additionally, this technology excels in creating smooth surface finishes, often eliminating the need for extensive post-processing—which not only enhances the visual appeal of the final product, but also reduces the time and cost associated with finishing, streamlining the production process.

2. Material Versatility

SLA technology supports a wide range of photopolymer resins, each offering different mechanical properties, colors, and transparencies. This versatility allows designers and engineers to choose the most appropriate material for their specific application. Different resins can also be selected to achieve varying degrees of flexibility, strength, and durability, enabling customization to meet the unique requirements of different projects.

3. Superior Surface Finish

Objects printed using SLA typically have a high-quality surface finish, which can often be used as-is without additional treatment, making it particularly beneficial for applications where surface quality is critical.

4. Accuracy

SLA is known for its ability to produce parts with tight dimensional tolerances. The kind of accuracy it has is essential for applications requiring precise fittings and mechanical functionality, such as in automotive or aerospace components.

5. Rapid Prototyping

SLA enables rapid prototyping, allowing designers and engineers to quickly create and test multiple iterations of a part. This iterative process is crucial for refining designs and reducing the development cycle time.

Challenges of SLA 3D Printing

Despite its advantages, SLA also presents some challenges:

1. Time-Intensive Post-Processing

After printing, SLA parts often require cleaning to remove uncured resin, followed by post-curing under UV light to fully harden the material. This additional step can be time-consuming and labor-intensive.

Objects with complex geometries may require manual removal of support structures, which can be laborious and may affect the surface finish.

2. Higher Material Costs

The resins used in SLA printing can be more expensive compared to other 3D printing materials like filament used in FDM (Fused Deposition Modeling), which makes SLA appear costly, especially for large production runs.

3. Speed Limitations

Since SLA printers offer more precision, its printing time can typically take longer compared to other 3D printing methods, particularly if you’re printing larger or more complex objects. The slow production can be a limiting factor for applications that require rapid manufacturing.

4. Creating Functional Parts

SLA parts can be brittle and unsuitable for functional prototypes. Moreover, while there is a variety of resins available for SLA 3D printing, the options for creating parts with specific mechanical properties are more limited compared to technologies like FDM or (Selective Laser Sintering) SLS 3D printing.

5. Material Handling and Safety

The liquid resins used in SLA printing can be hazardous, requiring careful handling, proper ventilation, and protective equipment to avoid skin contact and inhalation of fumes. It’s also worth noting that resins need to be stored under specific conditions to prevent degradation. Their shelf life can be limited, which might necessitate frequent purchases and inventory management.

Applications of SLA 3D Printing

Stereolithography (SLA) 3D printing is celebrated for its ability to produce highly detailed and precise objects, making it suitable for a wide range of applications across various industries.

1. Prototyping

SLA is extensively used in rapid prototyping. Designers and engineers use this technology to create prototypes quickly, allowing for fast iterations and modifications in the design process. This capability is crucial for reducing development times and costs, as prototypes can be tested and refined based on feedback.

Although SLA parts are generally brittle, they can be used to create functional prototypes that allow for visual and functional evaluation of the design. This is particularly valuable in the early stages of product development.

2. Jewelry

The precision of SLA makes it ideal for creating detailed jewelry pieces. The ability to produce fine details and smooth surfaces allows jewelers to create complex designs that would be difficult or impossible to achieve with traditional manufacturing methods.

SLA also supports the creation of custom designs tailored to individual preferences, making it popular in the bespoke jewelry market.

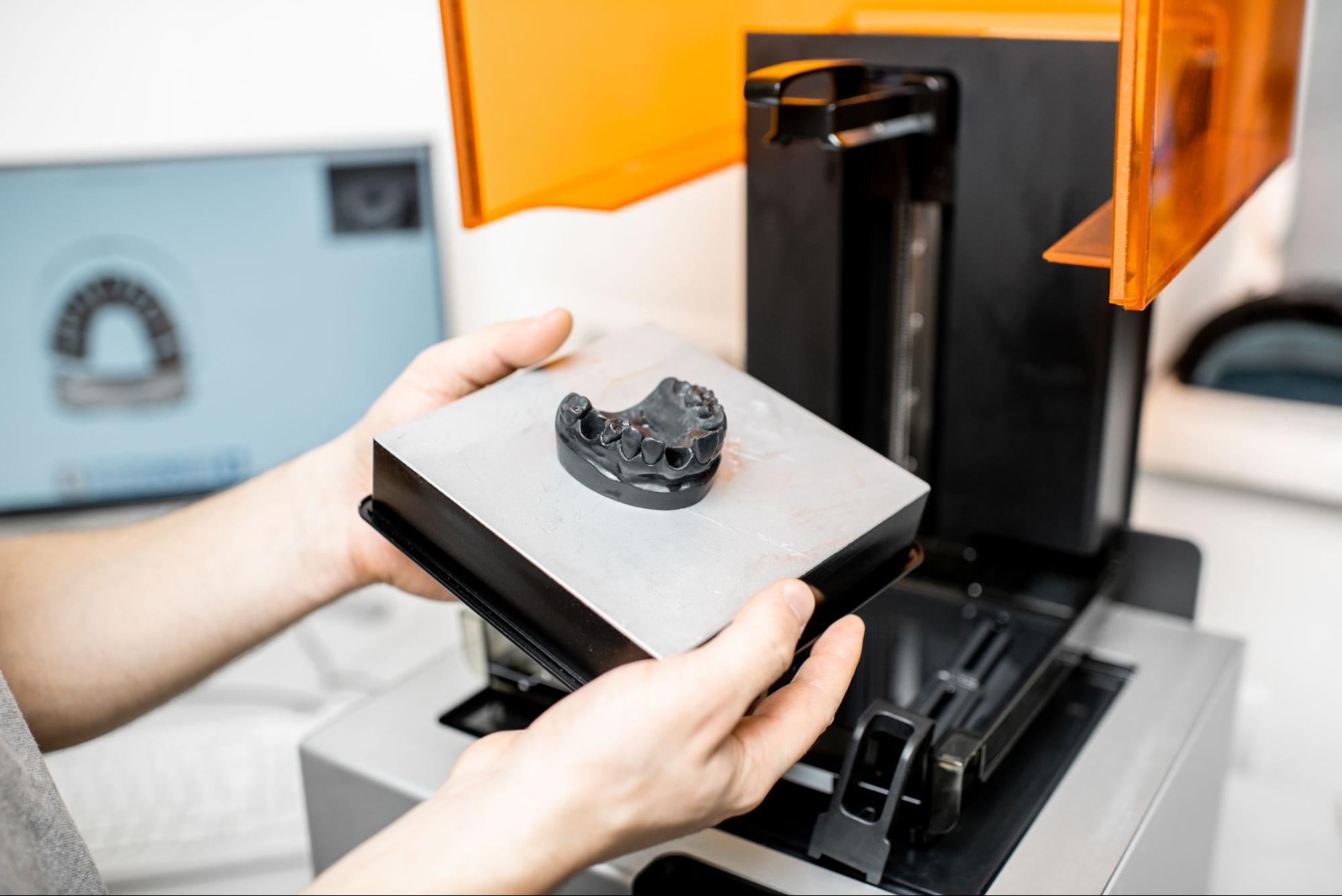

3. Dental Applications

SLA is used to produce high-precision dental models, which are essential for creating crowns, bridges, and other dental prosthetics. The ability to achieve detailed and accurate reproductions ensures a good fit and functionality of the final dental products.

The technology is also employed in the production of clear aligners, which are used in orthodontics for teeth straightening.

4. Industrial Applications

SLA is employed in manufacturing processes to create tooling due to its high precision, enabling the production of molds and tools that demand tight tolerances. While SLA parts are traditionally used for prototyping, advancements in materials have broadened its application to include the production of end-use parts. This expansion is particularly beneficial in industries where exacting precision and meticulous finishes are essential.

5. Art and Design

- Custom Art Pieces: Artists and designers use this technology for creating custom art pieces that feature complex geometries and fine details. It allows for the realization of innovative artistic concepts that push the boundaries of traditional sculpture and design.

- Architectural Models: Architects utilize SLA to create detailed models of their designs, providing a tangible representation of their projects with intricate details that are hard to achieve with other modeling techniques.

6. Medical Applications

- Surgical Models: SLA is used to create surgical models for preoperative planning. These models provide surgeons with a detailed representation of a patient’s anatomy, aiding in complex surgical procedures.

- Prosthetics: The technology is also employed in the production of custom prosthetics, where the precision of SLA allows for a better fit and comfort for the user.

Stereolithography (SLA) is a powerful resin 3D printing technology known for its precision and ability to produce high-quality, detailed objects, so understanding its fundamentals can help you leverage this technology effectively for your projects.

Looking for quality 3D printing in the Philippines? Contact us today to learn more about our products!