7 Tips on How to Choose the Right CNC Router

From hobbyists and small business owners to large manufacturing teams, selecting the right CNC router can dramatically improve your project outcomes. However, choosing the right one can still be daunting, especially with the vast array of options available in the market.

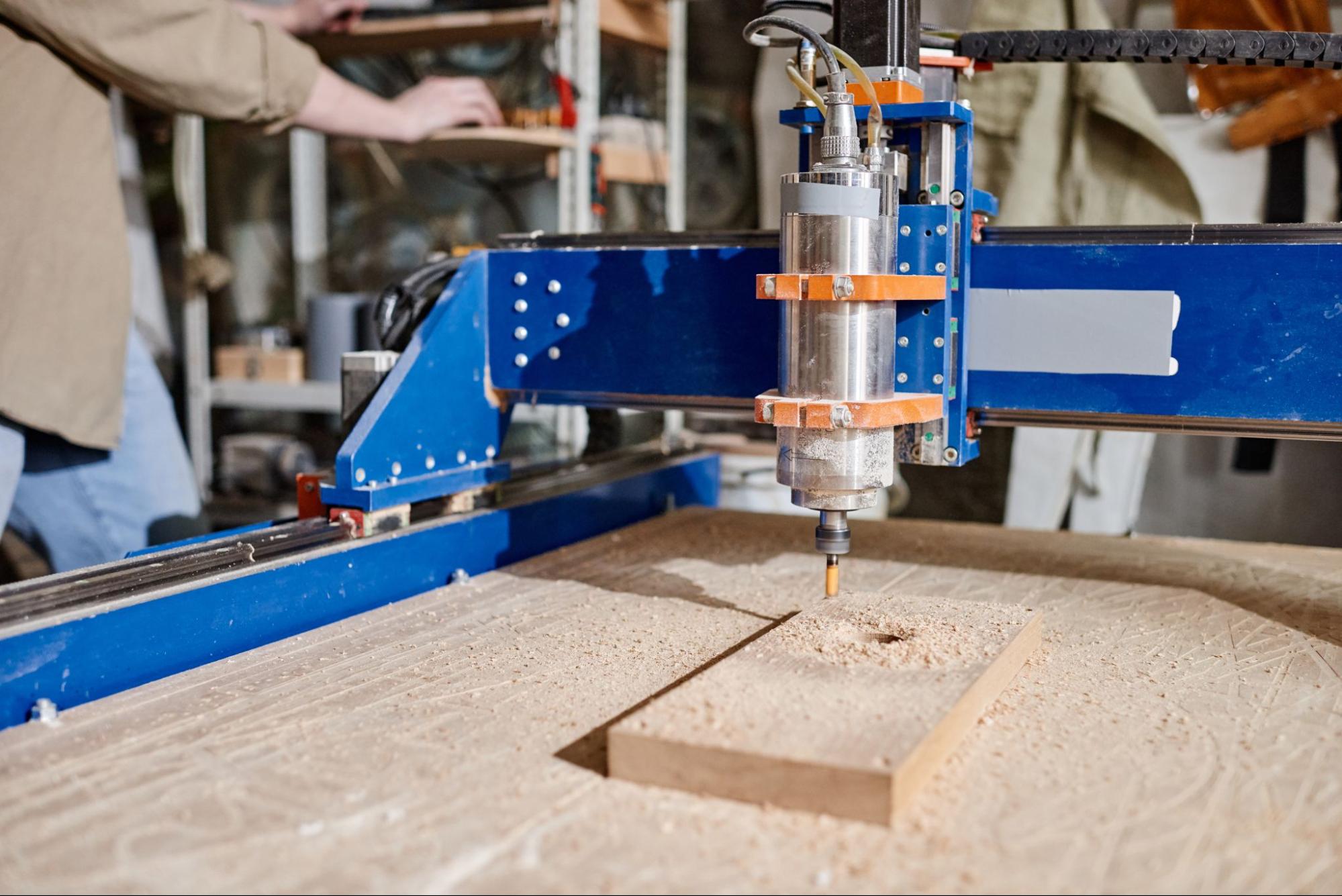

Before diving into the tips, it’s crucial to understand what a CNC (Computer Numerical Control) router is and how it works. CNC routers are automated cutting machines controlled by computers, used for cutting various materials such as wood, plastics, metals, and more. They are widely used in industries like woodworking, signage, and metalworking due to their precision and efficiency.

Related: CNC Router vs. CNC Milling: Should You Get One or Both?

Here are some tips to help you choose the right CNC router:

On This Page

- Determine Your Needs and Goals

- Consider the Features

- Think About the Budget

- Brand Reputation and Reviews

- Consider Future Needs

- Check For Ease of Use

- Safety Features

1. Determine Your Needs and Goals

Identify Your Projects

Consider the types of projects you plan to undertake. Are you working on intricate designs, large-scale productions, or custom one-off pieces? Knowing your primary projects will help narrow down the features and capabilities you need in a CNC router.

Material Compatibility

Different CNC routers are designed to handle different materials. See to it that the CNC router you choose can handle the materials you will be working with, whether it’s wood, aluminum, acrylic, or composites. Some routers are versatile and can handle multiple materials, which might be beneficial if your projects vary.

2. Consider the Features

Table Size and Working Area

The table size and working area of a CNC router are among its most critical features. They dictate the maximum material size you can handle. Make sure the working area accommodates your largest projects without sacrificing efficiency or accuracy.

Spindle Power and Speed

The spindle is the core component of a CNC machine. Higher power and speed allow for faster and more precise cutting, especially on tougher materials. Check the spindle’s power rating (measured in horsepower or kilowatts) and its speed range to ensure it meets your project’s requirements.

Precision and Accuracy

Precision and accuracy are essential in CNC routing. Look for routers that can repeatedly produce the same results with minimal errors. Precision is measured in micrometers, and higher precision means finer, more detailed cuts.

Software Compatibility

CNC routers require specific software for design and control. Go for a router that works well with the software you already know, whether it’s CAD/CAM or another design program. Using software that’s easy to navigate can greatly improve your workflow and productivity.

3. Think About the Budget

Initial Cost vs. Long-Term Investment

While it’s tempting to opt for a cheaper model, it’s advisable to think about the long-term investment. High-quality CNC routers may have a higher initial cost but often come with better durability, reliability, and support, saving you money in the long run.

Maintenance and Support

Regular maintenance is essential for the longevity of your CNC router. Check if the manufacturer offers good customer support, warranties, and easy access to replacement parts. Some routers might require more frequent maintenance, which can affect your overall budget.

4. Brand Reputation and Reviews

Check out different brands and read reviews from other users. Established brands are usually dependable and offer good customer service. Plus, user reviews can give you a sense of how well the routers perform in real-world situations and any issues you might encounter.

5. Consider Future Needs

If you plan to expand your business or tackle more complex projects, investing in a more advanced CNC router might be wise. Look for features that can be upgraded or expanded, such as additional axes or tool changers.

6. Check For Ease of Use

If you’re new to CNC routing, opt for a machine that’s easy to set up and operate. Look for routers that include detailed user manuals, online tutorials, and active user communities—they can provide valuable support and guidance.

7. Safety Features

Safety should never be overlooked. Make sure your CNC router has important safety features such as emergency stop buttons, protective covers, and good ventilation for handling dust and fumes.

By looking into the different aspects of CNC routers and aligning them with your projects, you can make an informed decision that enhances your productivity and precision. Remember, the right CNC router is an investment in your craftsmanship and creativity, so take your time to choose wisely. Feel free to reach out to manufacturers, join online forums, and connect with other CNC users to gather more insights and make a confident choice.

Looking for a quality CNC router in the Philippines? Contact us today to know more about our products!