Tips on How to Choose a 3D Printer

Are you thinking about purchasing a 3D printer in the Philippines for your business? Before you rush out to buy one, there are a lot of things to consider. With all of the different brands, models and types of 3D printers available on the market, choosing the right model can be a little overwhelming. This article will discuss the important factors to consider in choosing a 3D printer, so sit back and read on.

1. Compare Different Kinds of 3D Printing Technology

There are several types of printing mechanisms which 3D printers use, each with its own advantages as well as disadvantages. This will outline some of the most popular polymer printing technologies and how they compare against one another.

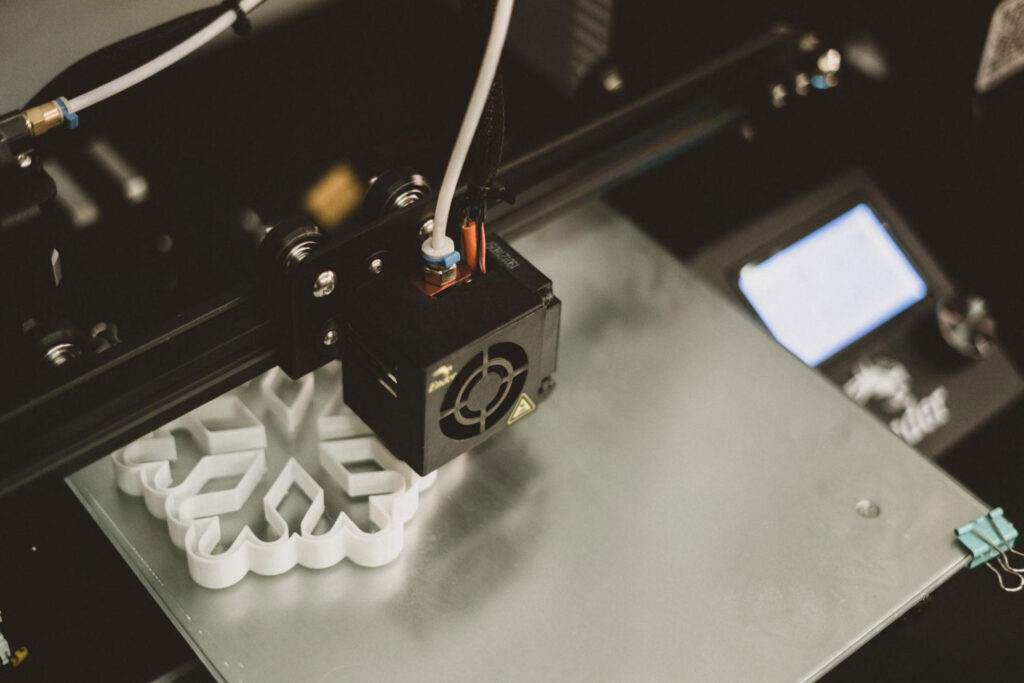

- Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the easiest, most common, and cost effective printing technology that is also known as Fused Filament Fabrication (FFF) or Plastic Jet Printing (PJP). In this process, a printer typically prints an object in successive layers by extruding a continuous length of printing material (like ABS or PLA filament) through a heated nozzle. This printer works its way up the model layer by layer.

- Stereolithography (SLA)

Stereolithography, also known as solid imaging, is one of the most popular processes for creating 3D models. SLA uses an ultraviolet (UV) laser to create layers of positive material that is solidified by an epoxy material called a photopolymer resin. The process itself is more complex than the others and the part output can be rather dense compared to other processes. However, SLA models are some of the best quality on the market, and if you have access to a 3D printer from this process, then it’s a great option for creators who want to make exceptionally high-quality designs or jewelry pieces for sale.

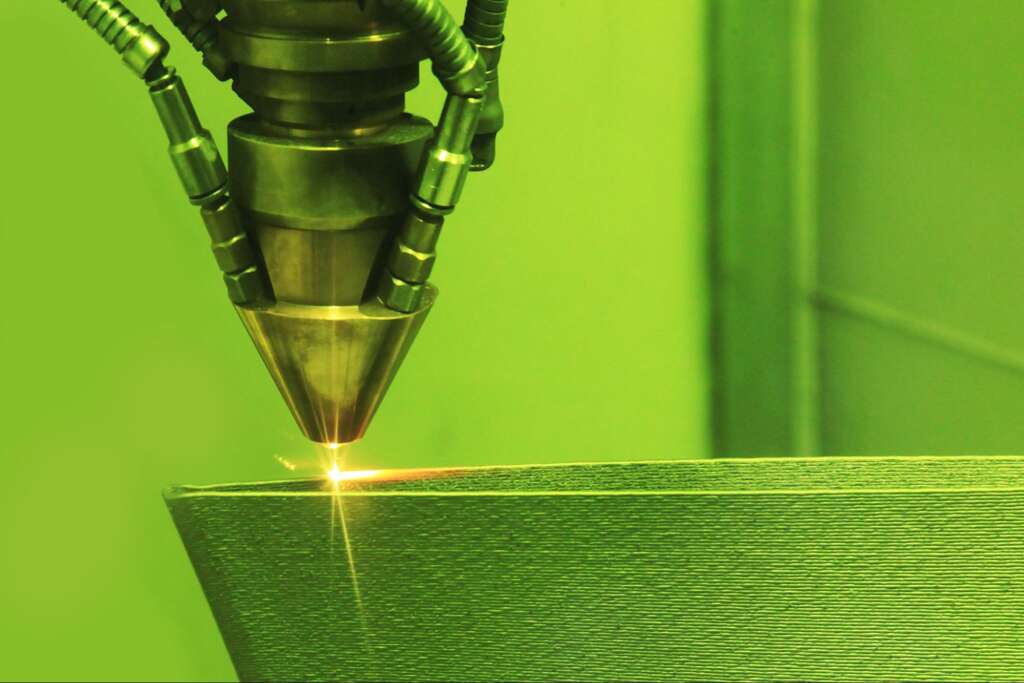

- Selective Laser Sintering (SLS)

Selective Laser Sintering, or SLS for short, uses a laser to melt and fuse powdered raw materials. This is in contrast to conventional methods that are used to manufacture plastic products from pellets like SLA and FDM printing technologies. SLS and these technologies share one thing in common — they build parts layer by layer. However, they use different technology to do it. In the case of SLS, the material used is placed in powder form on a bed where a laser then melts the powder together forming the parts layer by layer. This process takes place in an enclosed build chamber where parts are printed without the need for support structures (i.e. no scaffolding).

2. Find the Right Material for Your 3D Printer

There are many materials used in 3D printing. However, 3D printing material or filament is the raw material that feeds most of the printers. Filament is nothing but plastic in a long cable shape. The 3D printer heats up this plastic and extrudes it to make objects solid.

ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) are the two most common filaments. As both materials are thermoplastics, you can heat and cool them repeatedly to obtain the desired 3D shape. They both have their own strengths and weaknesses, but it’s mostly a matter of choosing the right filament for your needs.

3. Estimate the Size of The Object You Want to Print

The size of the object you want to print can help determine the build volume you are looking for in a 3D printer. Build volume is the maximum print size of a printer. It is usually indicated in inches or millimeters. Your computer or laptop screen will not let you visualize how large your object is, which is why sometimes it helps to have a physical representation of one.

4. Check The Printing Speed

The size of an object can play a factor in the speed at which your 3D printer prints. Generally, the larger the object you’re trying to print, the longer it will take to print. Higher resolution means more details, which in turn, requires slower printing speed. SLA technology usually sets the standard for production speed, but FDM is not far behind.

5. Determine Your Skill Level In 3D Printing

There’s a lot of excitement surrounding 3D printing, with the potential to change the way we produce consumer goods, clothing, and food products. 3D printers have been utilized in the past to produce everything from prosthetic limbs to tissue and heart valves. However, despite this exciting potential, there is a question about whether or not desktop 3D printers are ready for mainstream consumer use.

If you are new to 3D printing, then you are going to need a user-friendly printer. However, even with the most user-friendly 3D printers, it’s still going to take you some time to master. This can be frustrating if you’re just starting out as a 3D printing hobbyist or may be getting into it because of the potential to make money.

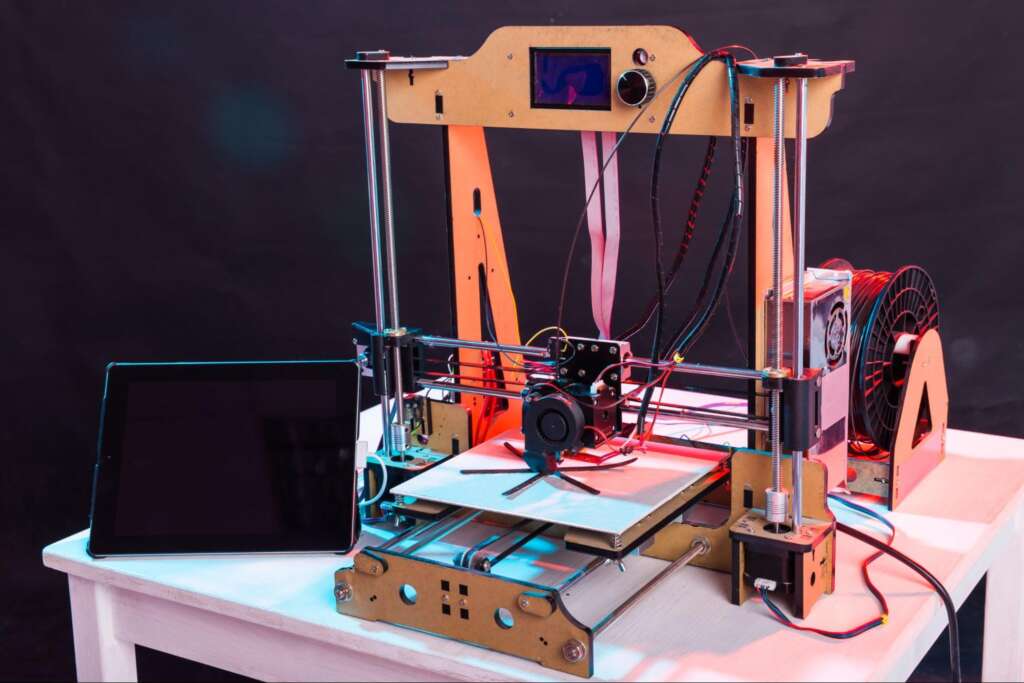

6. Consider The Location of Your 3D Printer

Like all technology from the future, 3D printers are expensive gadgets and cost a lot. Using it means having it somewhere close at hand, which can be somewhat of a hassle to get it working. There are two main requirements to have in mind: space and ventilation.

Keep your 3D printer in a convenient but safe location. Dealing with the plastic and melted scraps can be difficult, depending on the type of printer you have. As we mentioned earlier, ABS can produce hazardous smells that you won’t want floating around in your home.

3D printing is not only a fascinating concept to be used but it also allows you to explore your imagination and bring it into reality. It is essential for consumer electronics and varying applications in almost all industries because of its plethora of benefits. So, get on board the 3D revolution now.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!