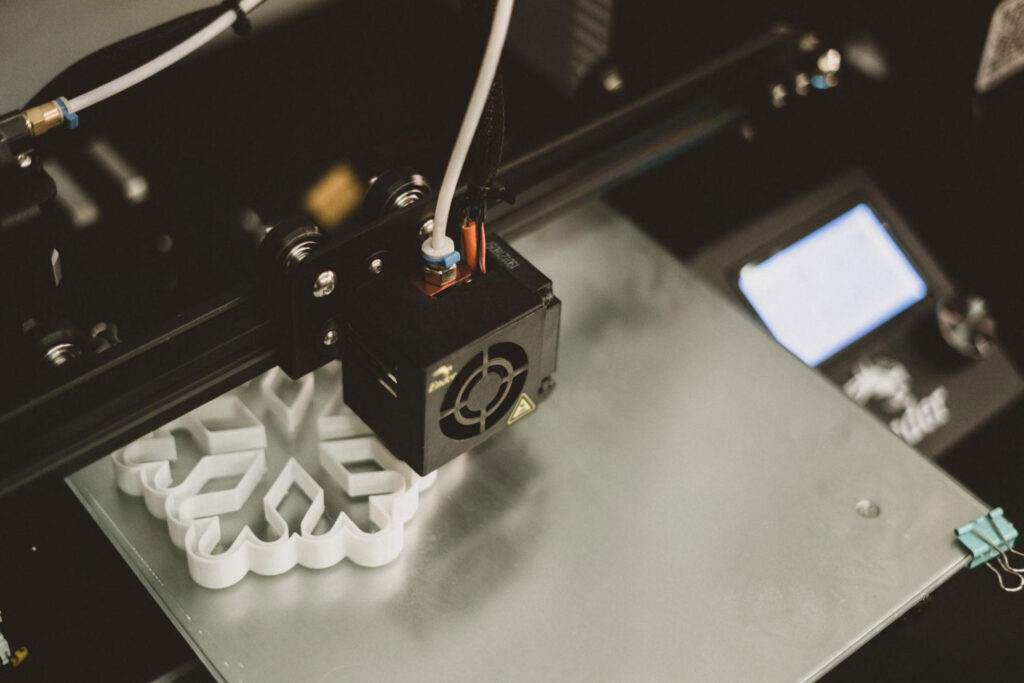

How to Maintain Your 3D Printer: 6 Tips and Tricks For You

As far as the reliability of your 3D printing goes, a well-maintained printer will be able to keep on churning out excellent prints, but an improperly maintained 3D printer will break down. Taking care of your 3D printer isn’t just about performing the occasional upgrade, maintenance, or modification. It’s about regular maintenance to keep things going smoothly and prevent those random hardware failures that can cost you lost time, bad prints, and even damage to the machine. There are some things you can do to ensure that your printer continues to function properly, and some common problems you should know about. Hopefully, these tips will help you make sure your printer is in good shape.

1. Clean the Extrusion Nozzle Before Printing

One of the most common mechanical problems that you’ll see with a desktop 3D printer is clogged extruders. A clogged extruder can cause a number of printing problems: The filament will jam as it comes out of the nozzle and causes the print job to fail. The material will also tend to sag down into the hot end which can cause melted or burned plastic to stick onto the nozzle. You may notice that your printed objects are poorly built, or have walls in places they shouldn’t. If an extruder gets jammed even slightly, it can cause stress on the rest of the machine, which will make your print less structurally sound than it should be.

2. Properly Store Your Filaments

While every filament has different levels of humidity sensitivity, many filaments will be made rough if exposed to a humid environment. Understanding how exposure to water will cause problems for your prints, and what you can do about it, may be helpful when choosing which filament to purchase. Many filaments are hygroscopic, meaning they soak up the water like a sponge. If a spool is stored in an area where it is exposed to air, or in an area where air flows freely around it, this humidity may cause the filament to be damp (or wet). This can be a big issue for filament manufacturers because the big-name brands need to ship their product to stores across the world — and in the process, exposing their coils to both hot and humid conditions along with vibrations that further break down these hygroscopic molecules.

3. Update Your 3D Printer’s Firmware

3D printers are equipment that contain lots of sensitive components, software, and electronics. Given the fact that these components are very important to the overall function of the printer, it’s wise to keep a close eye on new updates. As with many other electronics, 3D printers require regular checking and updating of the device’s firmware. If you don’t do this, your machine can run into several electronic problems, including bad connections and weak signals between the hardware modules.

4. Replace Your Worn Out Blue Tape

If your blue tape is looking a little worse for wear, we have the solution to your problem. The blue tape used to secure the print in place can wear out. As the edges of the tape start to deteriorate they can scratch away at the printing surface of your print which, ultimately, causes various problems in all of your 3D prints. This means that the print isn’t held down as securely as it would be when it was new, impacting the appearance and integrity of your models. In this case, the solution is simple and can be done in just a few minutes.

5. Upgrade Your 3D Printer’s Build Surface

Not only is build plate material an important factor in printing, but it’s also one of the easiest components to modify and upgrade. If you’re building your 3D printer, then you have to keep in mind the surface on your printer lays the print on. Choosing the right material is important because it affects the quality of the surface of your final product. A build plate is an essential part of a 3D printer and can make or break your builds. If you’re interested in printing larger parts, using different types of filament, or would like to try new materials, you’ll need to upgrade your bed surface to get the best results.

6. Lubricating Your 3D Printer is a Must

Lubricating your 3D printer at regular intervals is like oiling a machine. 3D printers have a lot of moving parts, and without the right lubricants, it is just a matter of time until they stop working. This can become very problematic, seriously affecting your printer’s efficiency. The correct lubrication of the moving parts of a 3D printer is a very important procedure to obtain good quality prints from a machine.

While 3D printing can be a lot of fun, it’ll only really serve its purpose if it can continue to be reliable. An un-maintained 3D printer is not going to accomplish anything but wasted time and frustration. Printer maintenance is certainly needed, and some printers are definitely more difficult than others – that should all be taken into consideration, as well. However, with a little bit of research, you can find some very basic things to keep your printer running smoothly, which will ensure that you’ll have a good time for years to come, printing out all kinds of exciting new things!

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!