How 3D Printing with Recycled Materials is Shaping Sustainable Manufacturing

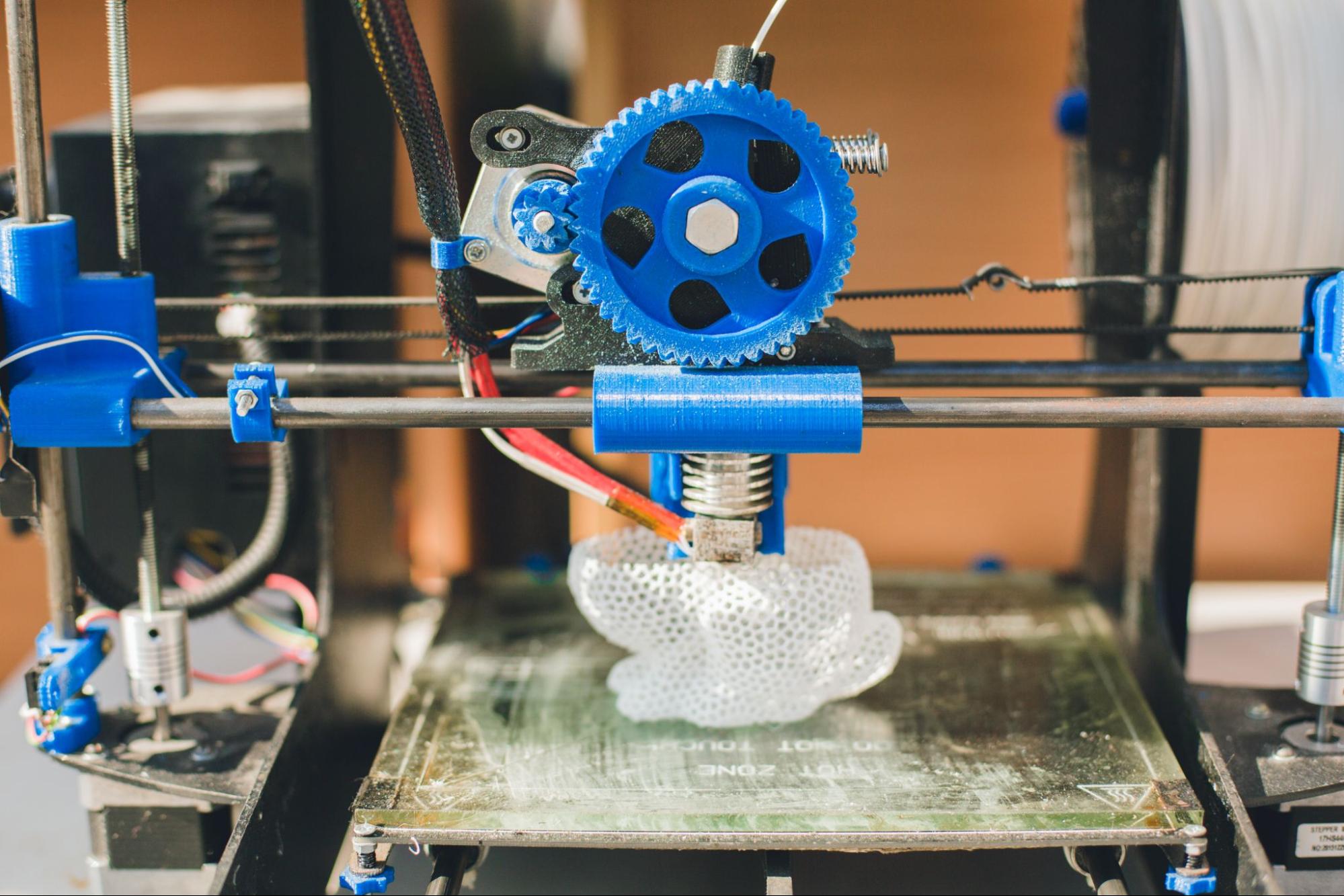

The world of manufacturing is experiencing a transformation, thanks to the rise of 3D printing. This technology provides innovative ways to produce products efficiently, cost-effectively, and with greater customization. But beyond its convenience, could it also be a game-changer for the environment? Incorporating recycled materials into 3D printing is pushing industries toward a more sustainable future. This shift helps cut down on waste, reduces carbon emissions, and makes production more eco-friendly.

On This Page

- The Role of 3D Printing in Sustainability

- Types of Recycled Materials Used in 3D Printing

- How 3D Printing with Recycled Materials is Transforming Industries

- 3D Printing in the Philippines: A Growing Market for Sustainability

- Challenges and Future Outlook

The Role of 3D Printing in Sustainability

Reducing Waste and Material Usage

Traditional manufacturing processes often lead to a significant amount of material waste. Think about subtractive manufacturing methods, where materials are cut, drilled, or carved out—leaving behind scraps that often end up in landfills. In contrast, 3D printing is an additive process, meaning it only uses the exact amount of material needed to create an object. This alone makes it a more sustainable option, but when combined with recycled materials, the environmental benefits multiply.

Lowering Carbon Footprint

Sustainability isn’t just about reducing waste; it’s also about minimizing energy consumption and carbon emissions. With 3D printing technology, products can be made locally, reducing the need for transportation and shipping. When using recycled materials, manufacturers further decrease their reliance on raw materials, reducing the demand for resource-intensive extraction and processing.

Types of Recycled Materials Used in 3D Printing

1. Recycled Plastics

One of the most common materials in 3D printing is plastic, and luckily, many types of plastic can be recycled and repurposed. Materials like PET or Polyethylene Terephthalate (commonly found in water bottles) and ABS or Acrylonitrile Butadiene Styrene (used in consumer goods) can be turned into recycled filament for 3D printers. Companies and researchers are developing innovative methods to collect plastic waste and transform it into high-quality 3D printing materials.

2. Metal Recycling in 3D Printing

Recycled metals such as aluminum, titanium, and stainless steel are increasingly being used in metal 3D printing. By melting down and reusing metal waste, industries can create strong, durable products without the need for new mining operations, which are both environmentally and economically costly.

3. Recycled Wood and Bio-Composites

Some 3D printing filaments incorporate recycled wood fibers, making it possible to print wood-like objects with a lower environmental impact. Additionally, biodegradable bio-composites, which mix organic waste materials with polymers, are being explored for sustainable 3D printing applications.

How 3D Printing with Recycled Materials is Transforming Industries

1. Sustainable Construction

3D printing is revolutionizing the construction industry by using recycled concrete and other repurposed building materials. Large-scale 3D printers can construct walls, homes, and even entire buildings while significantly reducing construction waste. This innovation is especially relevant in places like the Philippines, where sustainable building solutions can help address housing shortages while minimizing environmental impact.

The rise of building 3D printed houses in the Philippines is an exciting development, offering an affordable, eco-friendly alternative to traditional housing while utilizing recycled materials to further enhance sustainability.

2. Eco-Friendly Consumer Goods

More brands are embracing 3D printing with recycled materials to create sustainable consumer products. From furniture to eyewear, companies are finding ways to repurpose waste into new, stylish, and functional goods. This shift not only reduces reliance on virgin materials but also appeals to environmentally conscious consumers.

3. Automotive and Aerospace Applications

The automotive and aerospace industries are also tapping into recycled materials for 3D printing. Car parts, airplane components, and even entire vehicle structures are being produced with recycled metal and plastic filaments, cutting down waste and making transportation more sustainable.

3D Printing in the Philippines: A Growing Market for Sustainability

● The Rise of 3D Printing in the Philippines

The 3D printing industry in the Philippines is gaining momentum, with more businesses and individuals adopting this technology. As the country continues to develop, integrating sustainable manufacturing practices can help reduce waste and promote environmental responsibility.

● Local Innovations in Sustainable 3D Printing

Filipino innovators are exploring ways to use local recycled materials for 3D printing applications. For example, some initiatives focus on converting ocean plastic waste into usable filaments, addressing both marine pollution and manufacturing sustainability in one go.

● The Role of Fab Labs in the Philippines

Fab Labs (Fabrication Laboratories) are playing a crucial role in advancing 3D printing technology in the Philippines. These community-based workshops provide access to cutting-edge digital fabrication tools, including 3D printers, CNC machines, and laser cutters.

By integrating recycled materials into their projects, Fab Labs and innovations in the Philippines are helping to promote sustainable manufacturing and innovation at the grassroots level. They also serve as hubs for collaboration, enabling entrepreneurs, students, and researchers to explore eco-friendly production methods and drive local sustainability efforts.

Related: What is a Fab Lab? A Beginner’s Guide to Digital Fabrication Spaces

● Opportunities for Businesses and Entrepreneurs

With the increasing demand for eco-friendly solutions, businesses in the Philippines have a unique opportunity to invest in sustainable 3D printing. Whether through creating products from recycled materials or offering 3D printing services using eco-friendly filaments, the possibilities are endless.

Challenges and Future Outlook

Overcoming Material Limitations

One of the biggest challenges in using recycled materials for 3D printing is ensuring consistent quality and strength. Not all recycled plastics and metals are suitable for printing, and extensive testing is needed to develop high-performance filaments.

Scaling Up Sustainable 3D Printing

While 3D printing with recycled materials is promising, it still needs broader adoption across industries to make a significant impact. More investments in research and development, along with government and private sector support, can help accelerate this shift toward sustainable manufacturing.

The future of 3D printing with recycled materials looks bright. As technology advances, new methods of processing waste into high-quality 3D printing materials will continue to emerge. With more companies and individuals embracing sustainability, this innovative approach to manufacturing could become a mainstream solution for a greener future.

Ready to explore 3D printing opportunities in the Philippines now? Contact us today to learn more about our products!