How 3D Printing Enhances Reverse Engineering Workflows

In the world of design and innovation, reverse engineering plays a vital role in understanding and improving existing products or components. Traditionally, this process involved painstaking measurements, hand-drawn sketches, and physical molds. However, with the advent of 3D printing, reverse engineering has undergone a remarkable transformation, making it more efficient, precise, and accessible than ever before. Let’s explore how 3D printing enhances reverse engineering workflows and revolutionizes the way we approach design challenges.

On This Page

- What is Reverse Engineering?

- The Traditional Struggles

- How 3D Printing Enhances Reverse Engineering Workflows

- Real-World Applications

What is Reverse Engineering?

Reverse engineering is like solving a puzzle of a product’s design, breaking it down step by step to understand how it’s made and what it does. This also means looking closely at something already built, figuring out what it’s made of, and then making it again or making it better. This is really important in industries like cars, airplanes, and gadgets, where they’re always trying to come up with new and better things.

The Traditional Struggles

Before 3D printing, reverse engineering was a labor-intensive and time-consuming endeavor. Engineers faced challenges in accurately capturing complex geometries and intricate details of objects. Manual measurements and sketches often led to inaccuracies and discrepancies, resulting in lengthy iterations and potential design flaws. Moreover, reproducing components with unconventional shapes or internal structures was difficult using traditional manufacturing methods.

How 3D Printing Enhances Reverse Engineering Workflows

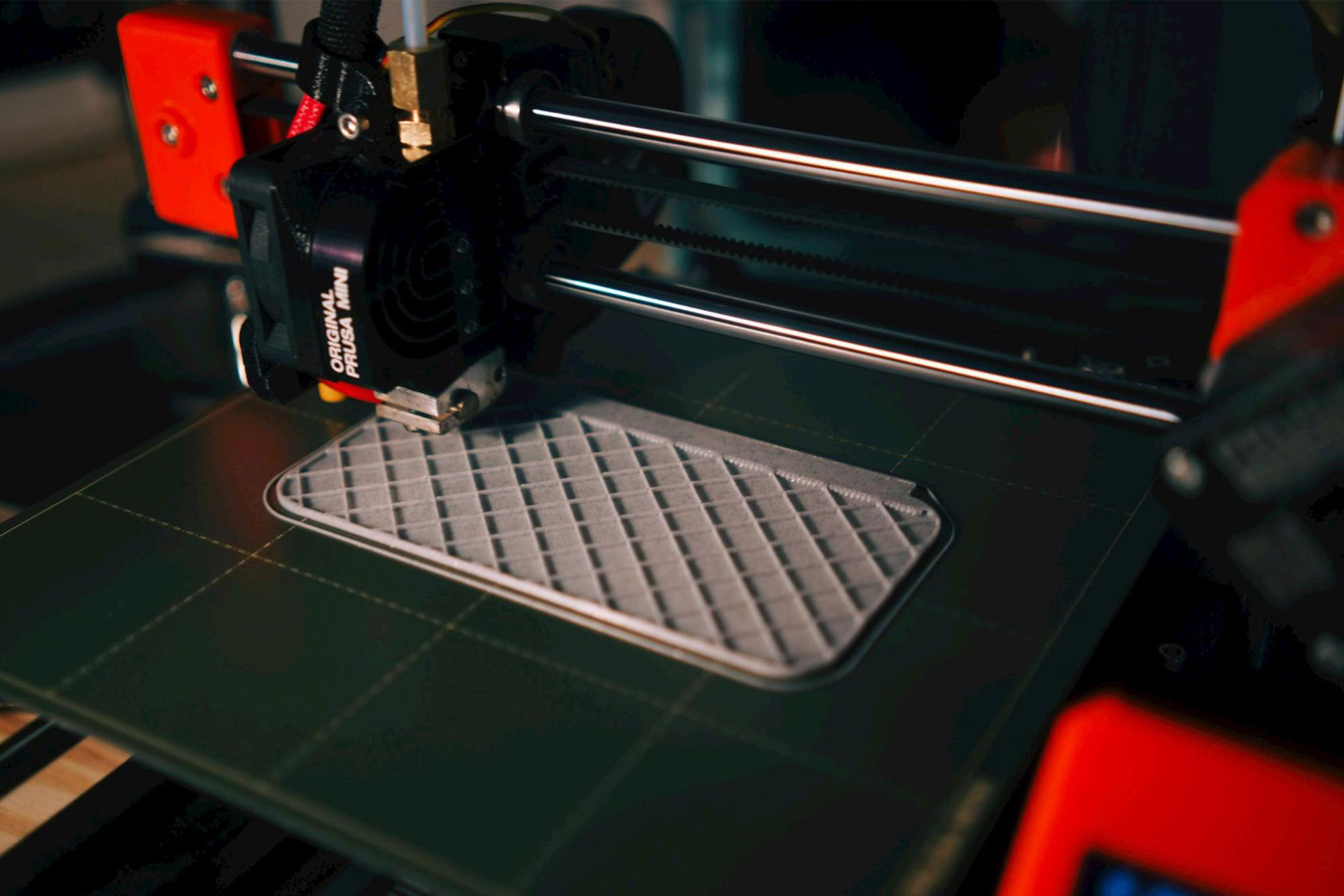

1. Precise Replication

One of the most significant advantages of 3D printing in reverse engineering is its ability to achieve precise replication of objects. With high-resolution scanning technology and advanced software, engineers can create digital models of existing components with remarkable accuracy. These digital models can then be translated into physical replicas using 3D printing technology, making sure that every detail is faithfully reproduced.

2. Rapid Prototyping

3D printing speeds up how quickly engineers make prototypes and try out new designs. Instead of waiting a long time and spending a lot of money on special tools, 3D printing lets them make prototypes whenever they need them. This makes it easier to try out different ideas and get new products to market faster, which encourages creativity and new inventions.

3. Complex Geometries Made Easy

3D printing is known for creating things with complicated shapes that are hard to make with regular methods. Whether it’s fancy patterns, weird shapes, or holes inside things, 3D printing can handle it with great accuracy. This helps engineers come up with new and cool designs and do things that were tricky or impossible before.

4. Cost-Effective Solutions

Cost considerations are paramount in any engineering attempt. The good thing is that 3D printing offers cost-effective solutions by minimizing material wastage and streamlining production processes. Unlike subtractive manufacturing techniques that involve cutting away excess material, additive manufacturing builds objects layer by layer, maximizing efficiency and reducing material consumption. Moreover, the ability to produce custom, on-demand parts eliminates the need for expensive tooling and inventory management.

Real-World Applications

The impact of 3D printing on reverse engineering extends across various industries, resulting in tangible benefits and driving innovation.

1. Automotive Industry

In the automotive industry, 3D printing is used for reverse engineering legacy parts, rapid prototyping, and customization. Additive manufacturing facilitates the recreation of obsolete components, improves design iterations, and accelerates product development cycles.

Related: How is 3D Printing Changing the Automotive Industry?

2. Aerospace Sector

In aerospace, 3D printing enables the replication of intricate aircraft components, optimization of structural designs, and production of lightweight parts. This leads to enhanced fuel efficiency, reduced maintenance costs, and faster turnaround times for spare parts.

Related: The 6 Benefits of 3D Printing Technology in the Aerospace Industry

3. Medical Field

In the medical and healthcare field, 3D printing revolutionizes reverse engineering workflows for prosthetics, implants, and surgical tools. Compared to traditional manufacturing methods, additive manufacturing offers personalized solutions, better patient outcomes, and shorter waiting times.

Related: 3D Printing in Healthcare: Uses and Applications

To sum it up, 3D printing has transformed reverse engineering workflows, offering unprecedented capabilities and efficiencies. From precise replication to rapid prototyping and cost-effective solutions, additive manufacturing empowers engineers to overcome traditional limitations and unlock new possibilities. As technology continues to evolve, the teamwork between 3D printing and reverse engineering will undoubtedly shape the future of design, manufacturing, and innovation.

Looking for quality 3D printing in the Philippines? Contact us today to learn more about our products!