Buying a 3D Printer: 5 Factors You Need to Know

3D printing has made its way into various industries as its benefits have built quite a positive impact and impression on professionals. The benefits of 3D printing have led to the increase of 3D printer users across the globe — with prototyping as its leading use. In the past years, it has been reported that 1.42 million units of 3D printers were shipped globally and it is still expected to get as far as 8.04 million units in the years ahead. Learning how to choose a 3D printer isn’t rocket science, however, to ensure that you get the best quality and functionality, it’s important to take into account a couple more factors you need to know when buying a 3D printer.

1. The Types of 3D Printers

3D printing is a technology that has evolved throughout the years to suit the needs, preferences, and requirements of its users. That’s why when buying a 3D printer, especially when you’re new to prototyping and creating product models, it’s important to know the different types of 3D printers that you can possibly obtain as each one differs in terms of what kinds of materials you can use to print, accuracy, function, cost, etc. The following types of 3D printers listed below are ones that are considered operational and still viable options at present.

- Fused Deposition Modeling (FDM)

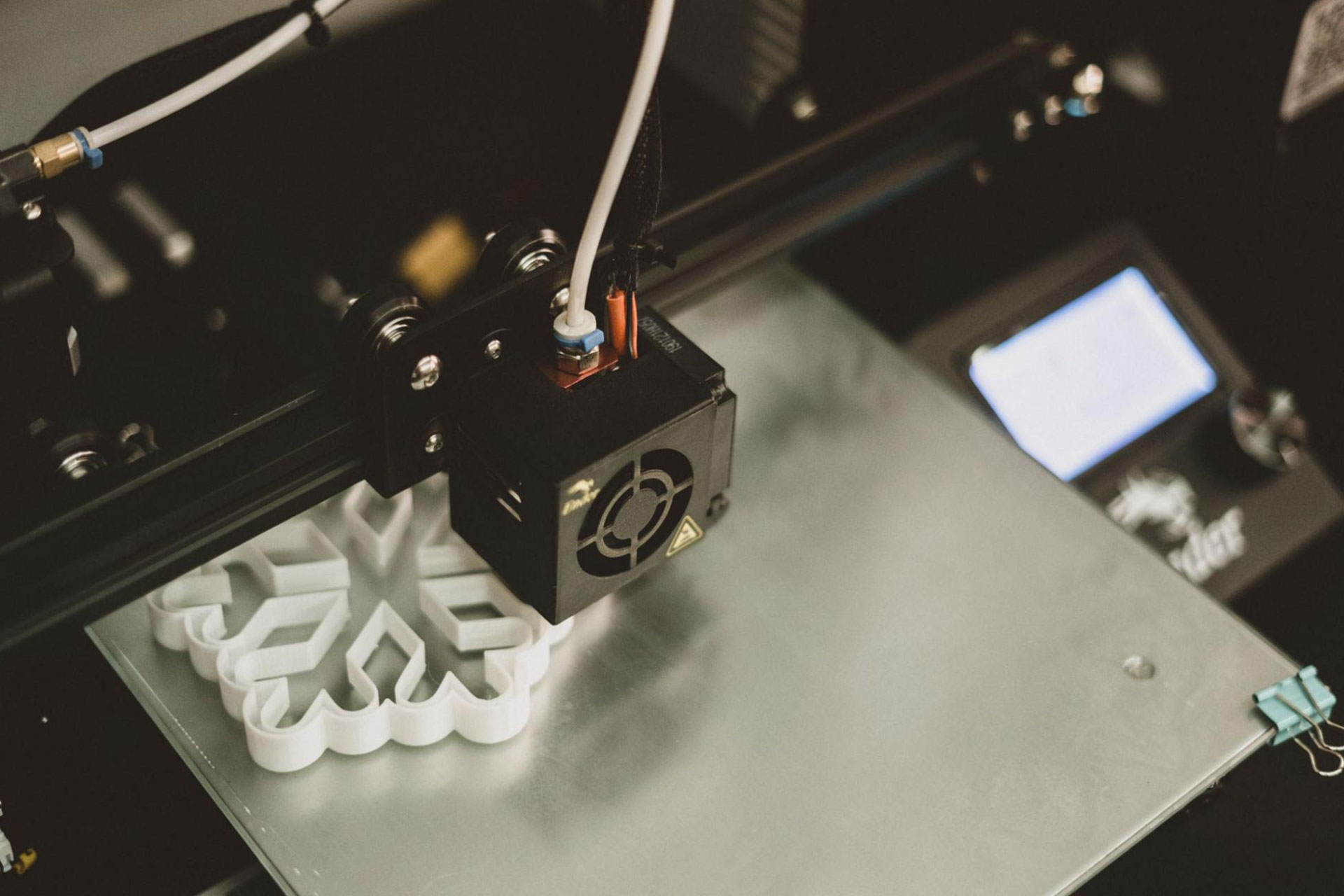

When it comes to popularity, Fused Deposition Modeling, or FDM, is winning in 3D printing technology. It is widely used in developing new products, prototyping, and product manufacturing. It is even used in affordable 3D printers and 3D pens. Using FDM allows you to print operational prototypes and ready-for-use products such as lego, plastic gears, and more. It can also be beneficial to mechanical engineers and manufacturers if they use FDM as anything printed with this type of 3D printer can proceed in high-performance and engineering-grade thermoplastic. And since FDM is the only 3D printing technology that uses production-grade thermoplastics, you can be sure that the products/items you print carry outstanding mechanical, thermal, and chemical characteristics.

Take note as well that compared to SLA (Stereolithography), FDM prints relatively slower. Printing small objects using FDM doesn’t take too long, however, with larger and more intricate parts, it will take time to finish.

- Stereolithography (SLA)

Stereolithography or SLA is the very first 3D printing technology that was invented by Chuck Hull in 1984, which has also become one of the most popular and is still a widely used type of 3D printing in today’s time. SLA is a resin-based printing technology that makes use of UV light beams on resin or other photosensitive fluid to harden it and develop a desired model or part. This allows SLA to have a higher quality of printed models or items.

As for the printing time of the objects, it will depend on the size of the SLA 3D printer you’re using, so see to it that you also look into what specific size will best fit your printing specifications. But if you’re wondering how long it will take for an object to be printed using SLA — just like any other type of 3D printer out there, you can expect that the larger the object is, the longer it will take to finish its printing process. SLA has a good printing speed, and it especially works well with printing small objects and models. So with this 3D printer, a small object would take 15 minutes to print, while a large house model would take a few days.

- Digital Light Processing (DLP)

Digital Light Processing or DLP is another type of 3D printer that was created in the late 80s — a few years after SLA was introduced. DLP makes use of digital micromirrors that are set out on a semiconductor chip. And just like SLA, DLP works with photopolymers. Although, they differ in terms of lighting source since SLA requires more light and uses UV laser beams, while DLP utilizes UV light from a projector. The printing speed of DLP stands out significantly because it prints large, dense objects fast. So if you’re looking to print large models and objects with a shorter build time, DLP is a fine option.

- Selective Laser Sintering (SLS)

Selective Laser Sintering or SLS utilizes a laser as its energy source to create a 3D printed model and object. It melts powdered plastic material and fuses them together to form a 3D-printed part. This particular 3D printing technology is one of the most up-to-date and dependable when it comes to additive manufacturing. SLS is suitable for printing highly complex parts and designs. With this 3D printer, you have a wide array of materials to choose from, which is why it is particularly known for printing customized goods.

2. The Price and Your Budget

The price of the 3D printer and your budget play a huge role when you’re planning to buy a 3D printer. This is because 3D printers have varying costs since they all have varying features, which means that some of them may be more pricey than others. It’s a good idea to look into their prices first then set a budget for when you decide to buy the 3D printer of your choice. Keep in mind as well that apart from the cost of the 3D printer are the cost of the materials you’ll be needing to print the models, so you may have to set aside a budget for that since their prices will vary straight with the cost of the 3D printer.

3. Quality of the 3D Printer

You shouldn’t fail to consider quality when you’re buying a 3D printer because this will affect the overall quality of your printed models and objects. Pay close attention to the printing speed as well as the printing resolution — the former highlights how fast an extruder can be moved by the printer, which also determines how fast a model can be printed; while the latter expresses the accuracy of the 3D printer. At the end of the day, remember that the best way to check the quality of a 3D printer is to check the quality of the printed models and parts. So it’s advisable to do your own research and check out some photos of the outputs of the 3D printer you’re eyeing for.

4. The Materials You’re Going to Use

Each and every type of 3D printer works differently, so they require different materials to support in order to form your desired model. For FDM, the most common 3D printing materials used are ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid) along with their other variants as they present higher heat resistance, impact resistance, chemical resistance, and rigidity properties, making them suitable for the printing method of FDM. As for SLA, it mostly makes use of resin formulations that carry an extensive range of optical, mechanical, and thermal properties that’s ideal for standard, engineering, and industrial applications. While for SLS, the 3D printing material options are limited compared to FDM and SLA. It especially makes use of nylon since it is lightweight, flexible, strong, and able to withstand chemicals, high impacts, heat, UV light, water, and dirt.

5. Safety Features

Safety shouldn’t be a neglected factor particularly when you’re thinking about using 3D printers in your home or an area where it’s within the reach of children. It’s vital to always take into account that 3D printers work with heat, so you have to be very cautious to prevent any accidents. See to it that you check the safety precautions that the 3D printer offers. For reference, there are some 3D printers where the nozzle automatically moves away once you pause or stop printing, and there are also some 3D printers with enclosures that serve as a protective case while printing.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!