5 Benefits of Pellet 3D Printing

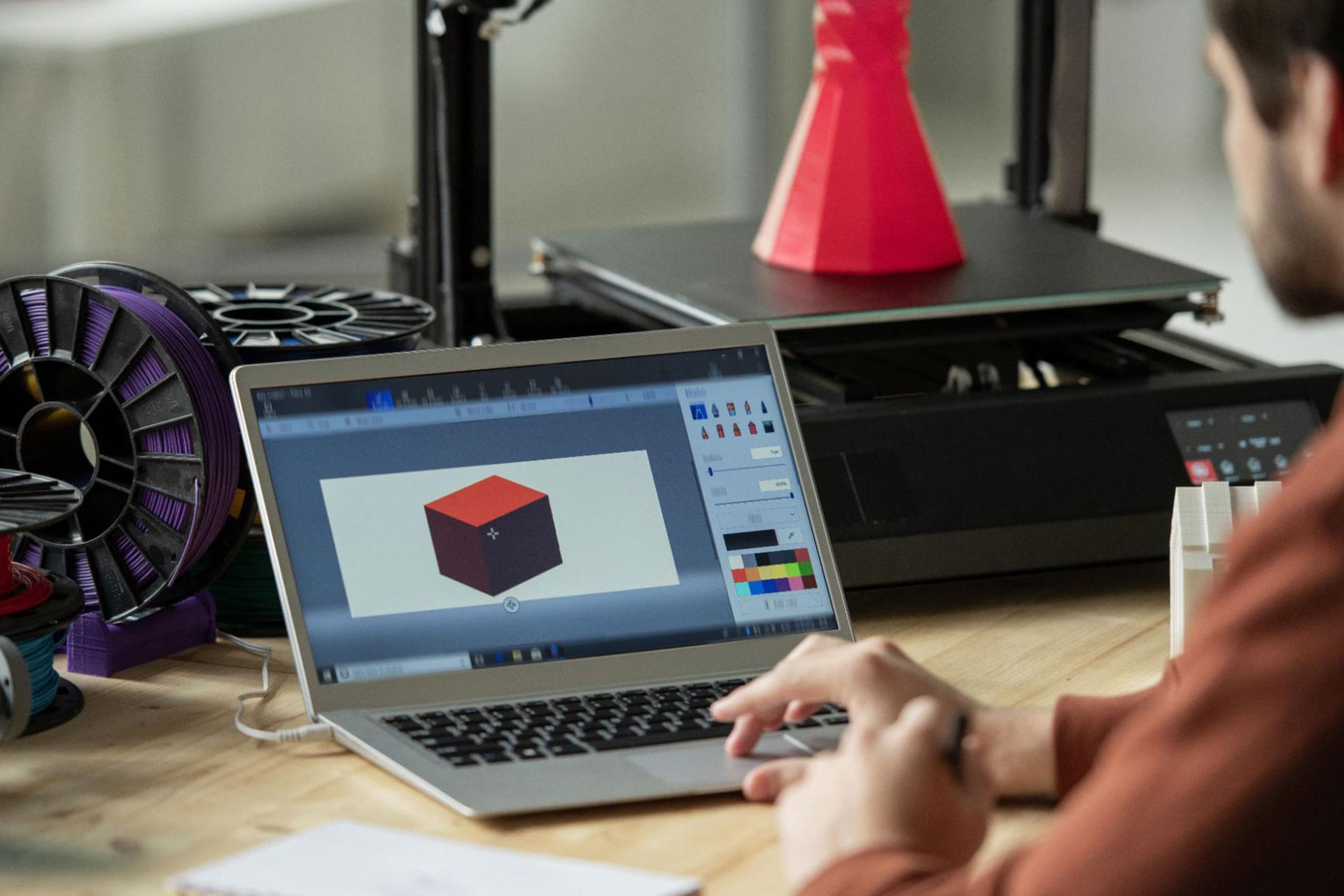

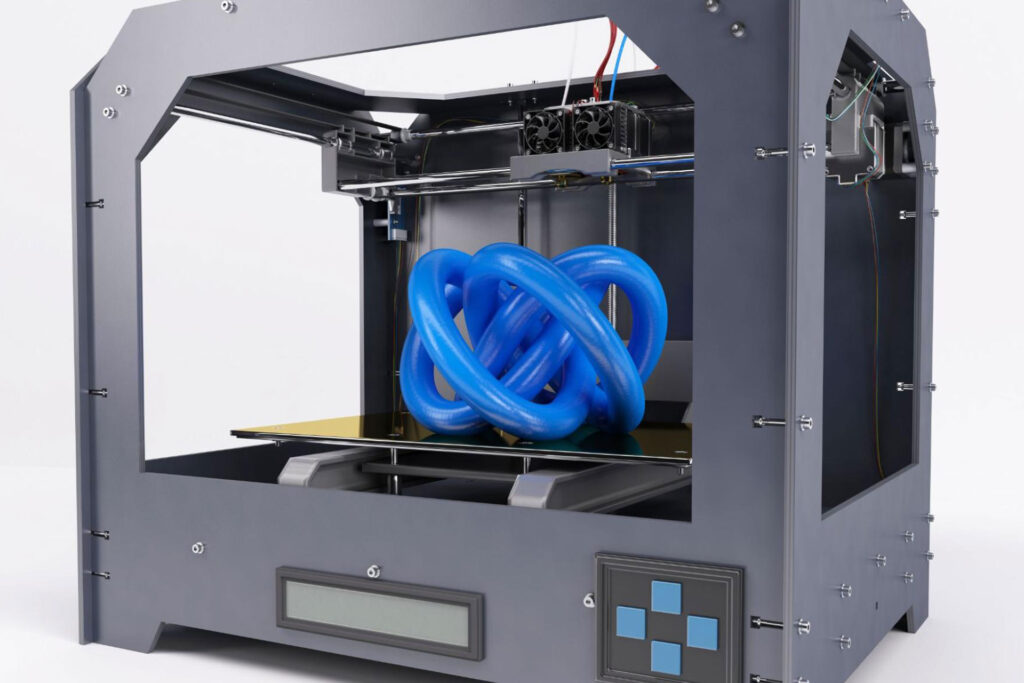

3D printing has many benefits like having faster finishing and simpler designs. In today’s technological advancements, one of the most popular and prominent machineries being used is 3D printing. But one big issue people have with 3D printing is the material cost. Filament for 3D printers are too expensive to afford, which is why people have found a way to cut material costs by more than 60% by printing with pellets and recycled plastics instead of filament

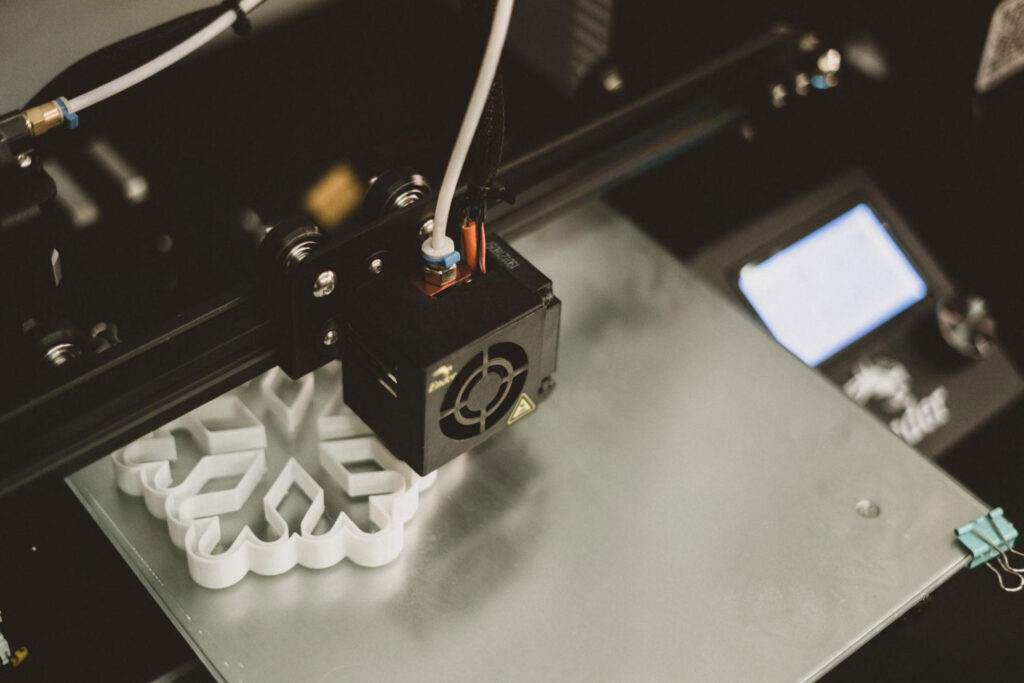

What is Pellet 3D Printing?

Pellet 3D printing, is a revolutionary process for manufacturing plastic parts, produces a higher quality product than simply extruding and stacking melted or granulated plastics. Also known as fused granulate modeling or FGM for short, is ideal for prototyping, small batch production of end-use parts, and custom fabrication. Unlike traditional plastic manufacturing with injection molding, pellet-based 3D printing uses recycled and consumer plastics: kits and toys, single-use medical devices such as syringes, bits of broken or outdated appliances. It also uses pellets made of raw polymers that can be ground into powder in an extruder to make different colors, strengths, and other variations in the final product.

What Are The Benefits Of Pellet 3D Printing?

1. Cost-Effective

Pellet 3D printing is cost-effective when you compare pellets with a filament of the same plastic. The bigger the volume and the longer the period, the less you pay per kilogram. Depending on your expected use (mass used or mass-produced), pellet 3D printing may well be cost-effective even when compared to terephthalic acid (TPA) based filaments such as PLA, ABS, and HIPS.

2. Faster Printing Speed

Because of the large heat zones, 3D printers using pellets can have a much higher printing speed than those using powder. In fact, pellet 3D printers are capable of printing at speeds nearly 100 times faster than FDM (Fused Deposition Modeling) printers. It’s also worth noting that this is accomplished while still using less power.

3. Printing Large Sizes Is Possible

3D printed furniture and large objects are often only economically feasible with cheaper materials and faster print times. Robotic arm 3D printers coupled with pellet-fed extruders are what manufacturers typically use for very large prints.

4. Custom Material

The benefit of using pellets for 3D printing is that you can mix your own plastic to create something amazing! Pellets are a great way of recycling as it allows you to print products completely out of recycled plastic. You will be able to print large objects, small objects, and anything in between. You could use pellets just as any other 3D printer filament but with the added benefit of being able to self-create unique plastics that only you have access to.

5. Environmentally Friendly

As the world becomes more and more aware of the damage that plastics are causing, 3D printing is being looked at as a revolutionary technology that could potentially save our planet. However, there are a few initiatives that have already proven effective in recycling post-consumer plastic waste, including collecting plastic cups to create filament for 3D printers.

It will be interesting to see how this technology develops in the coming years and how it could impact the world of additive manufacturing. This technology could prove to be a valuable tool for anyone in 3D printing, from hobbyists to big businesses. And it potentially eliminates direct and indirect waste associated with plastic production.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!