The 6 Benefits of 3D Printing in the Toy Industry

With 3D printing transforming the way businesses from various industries work, it’s no surprise that it has also made its way into the toy industry. And it is through the ability of this technology to create intricate, customizable, and cost-effective toys that revolutionized the way we think about playtime.

Related: 5 Ways 3D Printing Helps Businesses

In this article, we’ll delve into the exciting world of 3D printing in the toy industry and explore the benefits it brings to both manufacturers and consumers.

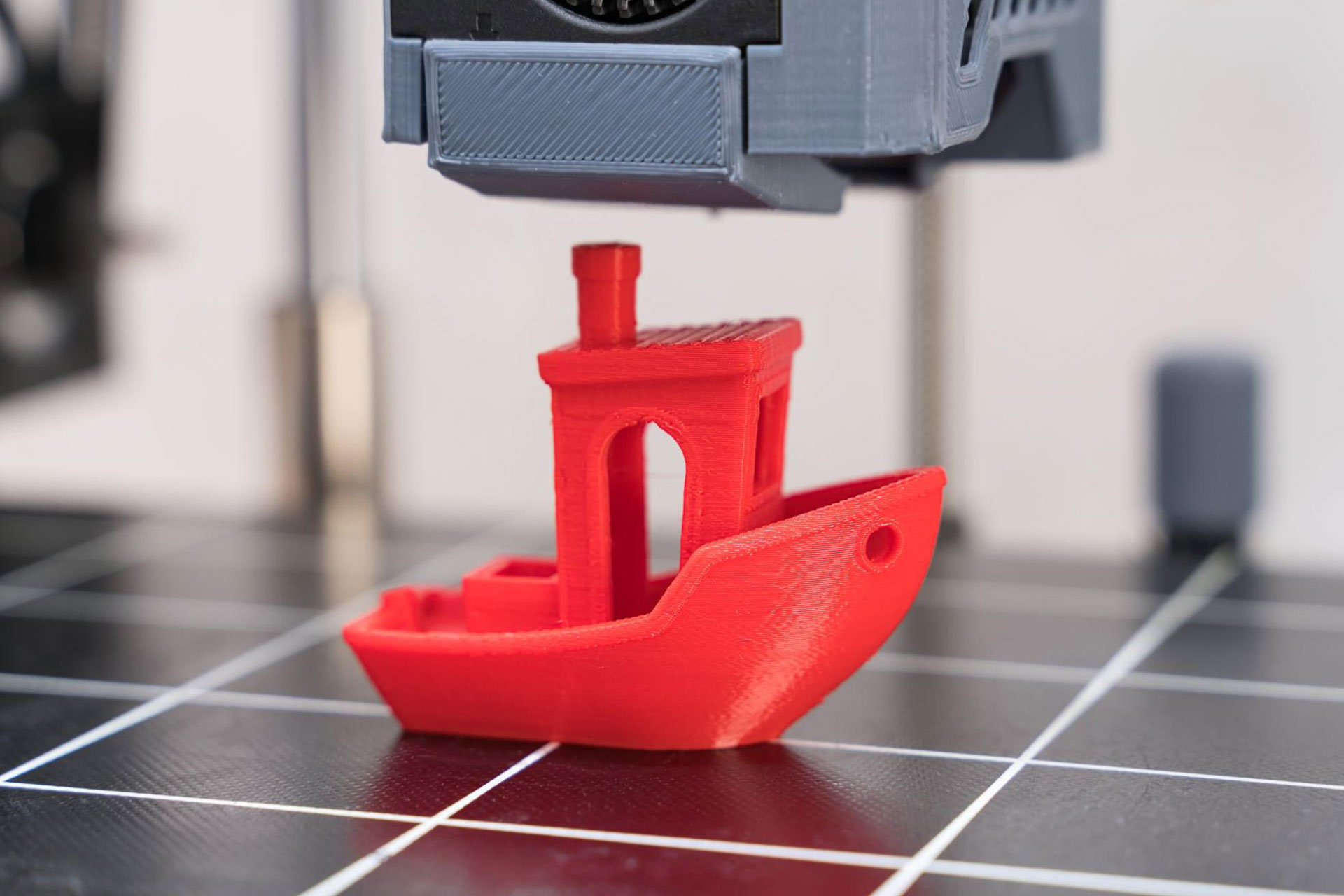

A Brief Introduction to 3D Printing

Before we dive into the advantages of 3D printing in the toy industry, let’s briefly understand what 3D printing is all about. 3D printing is an additive manufacturing process that builds objects layer by layer from a digital 3D model. Unlike traditional manufacturing methods, which involve subtracting material (like carving wood or machining metal), this technology adds material only where it’s needed, making it incredibly efficient and versatile.

Now, let’s see how this innovative technology is reshaping the toy industry.

1. Customization Galore

One of the most significant benefits of 3D printing in the toy industry is the unparalleled level of customization it offers. Unlike traditional manufacturing processes, involving mass-production of identical toys that limit choices for consumers, it allows for customization of toys to suit individual preferences.

Personalized Toys for Every Child

Whether it’s a superhero action figure with your child’s name on it or a custom-designed puzzle, 3D printing enables the creation of toys that resonate with the child’s imagination.

Educational Toys Tailored to Learning Styles

Educational toys are also benefiting from 3D printing. Teachers and parents can design educational tools that match a child’s learning style. For instance, tactile learners may benefit from 3D-printed models, while visual learners can explore custom-made infographics and diagrams.

Related: 3D Printing in Education: 6 Essential Benefits

2. Rapid Prototyping and Innovation

Innovation is key in the toy design world. With the use of 3D printing, it provides toy manufacturers with a powerful tool for rapid prototyping and testing new concepts. This speed and flexibility lead to more exciting and diverse toys on the market.

Faster Design Iterations

Traditional toy design can be time-consuming and costly, often involving molds and tooling. With 3D printing, designers can quickly create prototypes, evaluate them, and make necessary adjustments, significantly reducing time-to-market.

Encouraging Creativity

The ease of prototyping also encourages creativity among designers. They can experiment with new ideas without the fear of excessive production costs, resulting in more imaginative and innovative toys.

3. Sustainable Manufacturing

Sustainability is a growing concern in every industry, and the toy industry is no exception. 3D printing promotes eco-friendly manufacturing practices in several ways.

Related: Is 3D Printing Eco-Friendly? How 3D Printing Reduces Waste

Less Material Waste

Traditional manufacturing methods often produce a substantial amount of material waste due to the need for molds and excess materials. 3D printing is an additive process, meaning it uses only the material required, resulting in minimal waste.

Localized Production

By enabling local production, it reduces the need for long-distance transportation of toys, cutting down on carbon emissions associated with shipping. This localized approach can also support small-scale toy manufacturers and designers.

4. Cost-Effective Production

While 3D printing technology was once considered expensive, it has become more accessible and cost-effective over the years. This affordability brings several benefits to both manufacturers and consumers.

Reduced Manufacturing Costs

It eliminates the need for expensive molds and tooling, significantly lowering production costs. This cost-saving advantage can be passed on to consumers, making high-quality toys more affordable.

Affordable Customization

Customization doesn’t have to break the bank. With 3D printing, even personalized toys can be reasonably priced, opening up new opportunities for toy manufacturers to cater to niche markets.

5. Safety and Quality Control

Ensuring the safety and quality of toys is paramount, and utilizing this technology allows for precise control over the production process, enhancing safety and quality.

Consistency in Production

Unlike traditional manufacturing, 3D printing produces consistent results with minimal variation between products. This guarantees that each toy meets stringent safety standards.

Materials Selection

Toy manufacturers can choose from a wide range of materials suitable for 3D printing, ensuring that toys are not only safe, but also durable and long-lasting.

6. Bridging Gaps in Accessibility

3D printing has the potential to bridge gaps in toy accessibility, especially for children with disabilities. Customized toys can be designed to meet specific accessibility requirements, ensuring that every child can enjoy playtime to the fullest.

Looking for quality 3D printing in the Philippines? Contact us today to learn more about our products!