3D Printing vs. 4D Printing: How Are They Different From Each Other?

Manufacturing different products have taken a huge step forward throughout the years because of technological advancements. What used to be manually produced is now being created using digital tools and equipment to lessen manual labor and produce more efficient results. 3D printing is an example of technology that has been changing the way manufacturing is being done by various companies from different industries. Along with it is 4D printing, which of course, is another technology innovation that aims to provide ease in the manufacturing process and enhance the outcome of the manufactured products

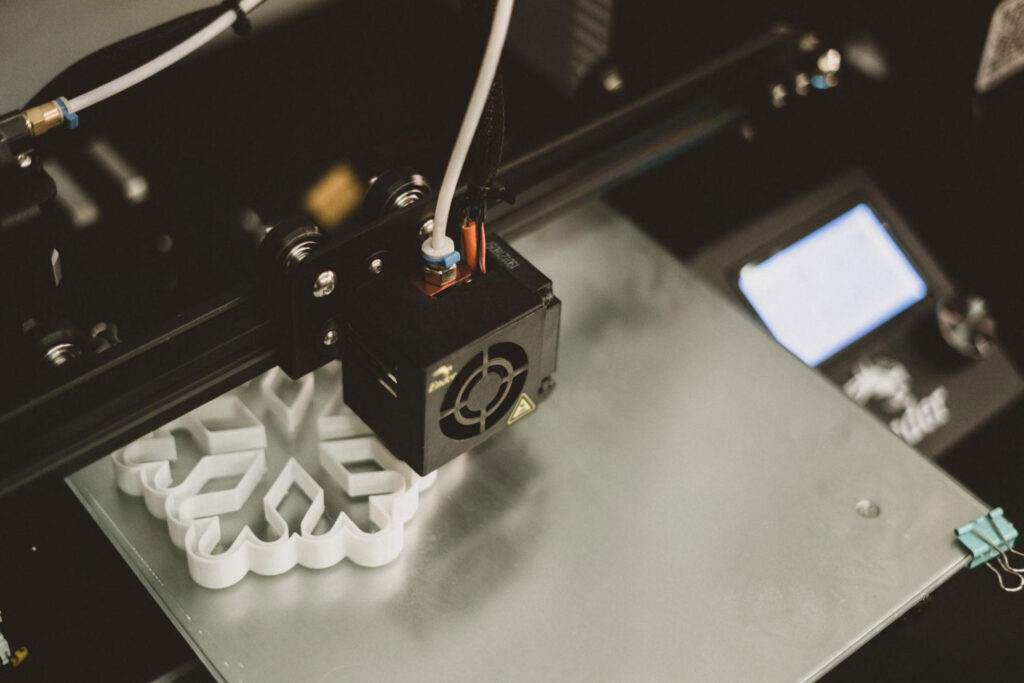

What is 3D Printing?

3D printing is a process that allows you to create three-dimensional objects, parts, or prototypes layer by layer using a digital design. This technology that’s also known as additive manufacturing is able to produce even the most intricate geometric shapes, can typically print fast and doesn’t require that much manual processing to accomplish a task compared to the traditional way of manufacturing, helping to reduce build time and labor costs. 3D printing is widely used in various industries today and has been beneficial for businesses in the past years.

What is 4D Printing?

4D printing is a method by which a 3D printed object or part is transformed into another structure using different energy sources such as light, temperature, and other environmental stimuli. It puts on a specific geometric code to the process that’s established from the angles and dimensions of the desired shape. Simply put, 4D printing utilizes 3D printing techniques, customized designs, as well as modern and unique materials to morph a 3D printed object or part into another form. It is also a technology that provides a way to increase the efficiency of manufacturing products while aiding in the reduction of manufacturing costs.

How does 3D printing differ from 4D printing?

Both 3D printing and 4D printing are products of technology innovation that were built to enhance production quality and efficiency in the manufacturing processes. But of course, since technology evolves, we cannot neglect the fact that these two have differences. So with that being said, we’ll be highlighting some factors to help you circle in on their differences:

Outputs

With 3D printing, the object doesn’t change and stays on a fixed form or shape just like any other plastic or metal parts after they are manufactured; whereas with 4D printing, the object transforms over time when it is exposed to stimuli such as heat, water, and light

Applications

3D Printing Applications:

- Pharmaceuticals

- Biomedical Implants

- Educational Materials

- Prosthetics and Human Organs

- Customized Clothing

- Houses

4D Printing Applications:

- Human and Animal Implants

- Sensors for Infrastructure Lines

- Medical Devices

- Home Appliances

Potential Use in the Future

In terms of potential use in the future, both of these technologies would still need more refinement before it can completely replace the traditional way of manufacturing as they both have their limitations. 3D printing, as seen in its capabilities, can continue to be useful in many different fields, focusing on the efficiency of fabrication, application, and new product designs. 4D printing, on the other hand, can be of extreme significance to manufacturing-related industries because of its ability to develop materials that can transform based on the environmental stimuli, resulting in the object to assemble by itself — thus, helping to give ease in the manufacturing process. However, as we have mentioned previously, they will both have to continuously be worked out and more research and testing has to be done in order to render them totally capable of being the first options for manufacturing products.

Compared to 3D printing, 4D printing is relatively younger since it was invented years after 3D printing made its first mark. So you can say that little is known about 4D printing compared to 3D printing. However, both have been revolutionizing the way manufacturing is done today as they create an impact on the speed of manufacturing as well as the costs. If you would ask which one is better, the answer is: it will depend on your specifications because they both have their benefits that can possibly suit what you are looking for.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!