7 3D Printing Trends in 2023

3D printing is not a new technology as some may perceive it to be a 21st-century innovation because of its design and features. It was invented several years ago, and in the past few years, it drew more recognition and awareness, especially for industries such as healthcare, manufacturing, aerospace, robotics, construction, and more that are in need of creating complex and intricate parts and prototypes quickly and cost-effectively. Technology evolution as well as the growing needs of people for handy innovations to improve life has also enabled the progressive improvement of 3D printing throughout the years, expanding its capabilities in creating high-quality prototypes and products.

That’s why today and in the years to come, we will be seeing more of how 3D printing will continue to revolutionize the world. With that, let’s look at the 3D printing trends in 2023:

1. Novel Materials

Gone are the days when 3D printing was only limited to materials such as polymers because today, we are presented with more options for materials to use. To ensure better print quality, novel materials such as ceramics, wood, metal, and stone are now being used to create high-performance parts that are strong and durable.

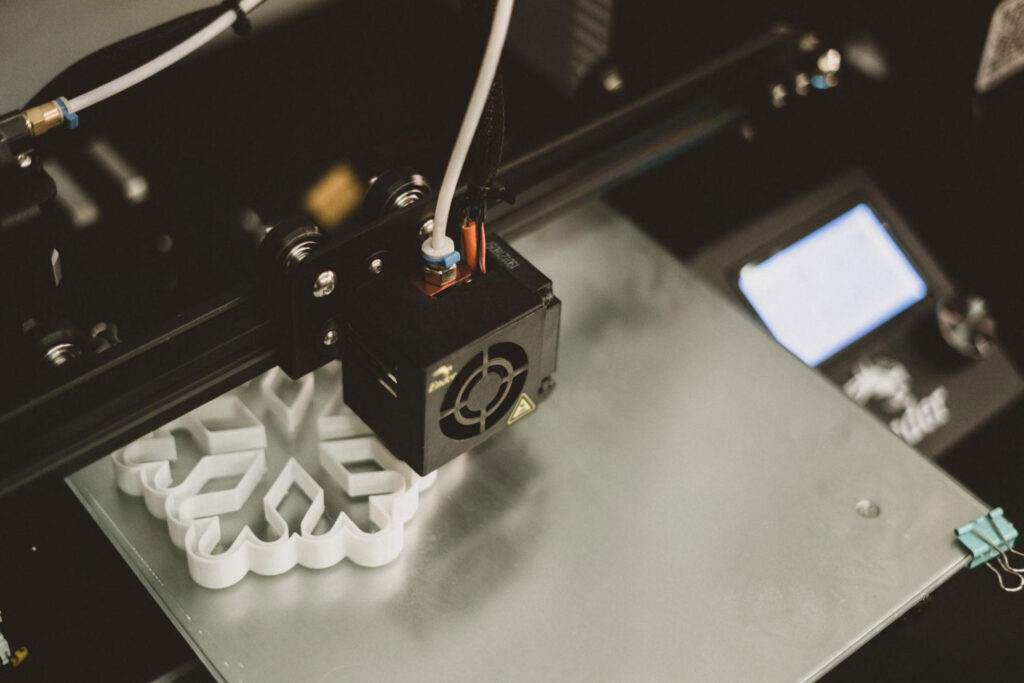

2. Rapid Prototyping

3D printing is being utilized in rapid prototyping to speed up the process and save money — hence why you can also expect 3D printers to offer higher performance and design software to hasten the prototyping process and development. Furthermore, 3D printing-generated rapid prototyping also removes the need for manual labor and errors, making the process more cost and time efficient.

3. Added 3D Printing Innovations in the Medical Field

The healthcare and medical industry have been one of the industries to greatly benefit from 3D printing, which is why it’s also no surprise that the medical field will be making use of more 3D printing innovations this year.

3D printers are known to produce highly precise parts and models for the healthcare industry such as surgical instruments and even custom-made prosthetic devices that assist in complex operations and provide convenience to patients. So you can expect that even human tissue can be 3D printed. Yes, you read that right! A collaborative research within the University of Minnesota’s Department of Radiation Oncology was able to put together specialists across different disciplines that are using advanced imaging, computational modeling, and artificial intelligence to create 3D-printed human tissue.

Related: 3D Printing in Healthcare: Uses and Applications

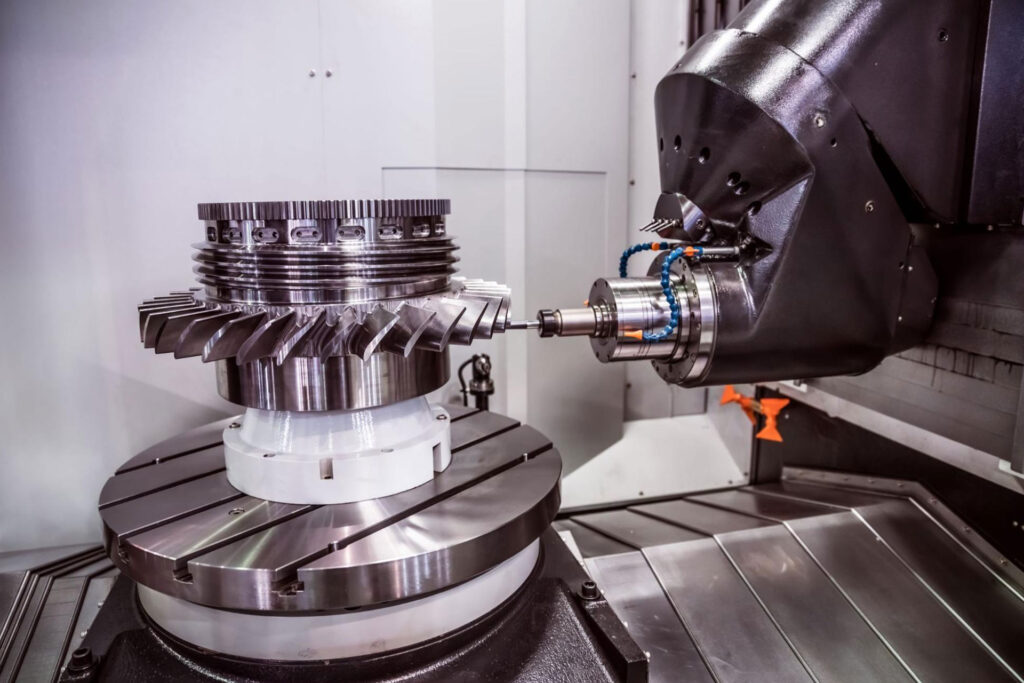

4. Bigger Production Volume

Mass production hasn’t always been a strong suit for 3D printing compared to the conventional way of manufacturing. It has the potential to transform mass production, however, there will be some challenges to that since some parts can be difficult to print. But with advances in technology, materials, and workflow automation software, it now enables 3D printing to produce parts at a bigger volume.

5. Advanced 3D Printers

We’ll be seeing more growth and functionality from 3D printing this year. Startups are looking to improve the performance of 3D printing by providing innovative 3D printers tailored to the specific additive manufacturing needs and processes of users. In addition, advances added on to 3D printers enhance the degree of movement of printer arms, which is helpful in reducing the energy requirements for additive manufacturing processes, and also lessens the cost of 3D printing workflows.

6. Additive Manufacturing Automation

You can anticipate more automation since startups are offering printer-agnostic solutions that will help automate and improve additive manufacturing processes. Automating 3D printing also lessens manual labor costs and errors, and allows for rapid prototyping to enhance print flexibility and reduce waste, on-demand manufacturing, and part development.

7. Better Supply Chain Performance Through 3D Printing

The pandemic has caused a massive negative impact on a lot of things, and it includes the supply chain. Given the disruption in supply chain management, cost-efficiency was considered more important by the logistics management than resilience since the pandemic, which also resulted in a decline since resilience was compromised. However, there has been a shift in the goal. So instead of focusing only on cost-efficiency, building supply chain resilience is now of top priority across different industries.

Fortunately, 3D printing came to the rescue, and offers remarkable benefits for companies who have built reliance on weak supply chains. With the usual long stages of design and production, 3D printing becomes handy since it can reduce production time, saving both time and money in the production process. On top of that, it allows for better utilization of materials, creating less waste in resources — which is crucial if there are supply chain disruptions.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!