3D Printing in Healthcare: Uses and Applications

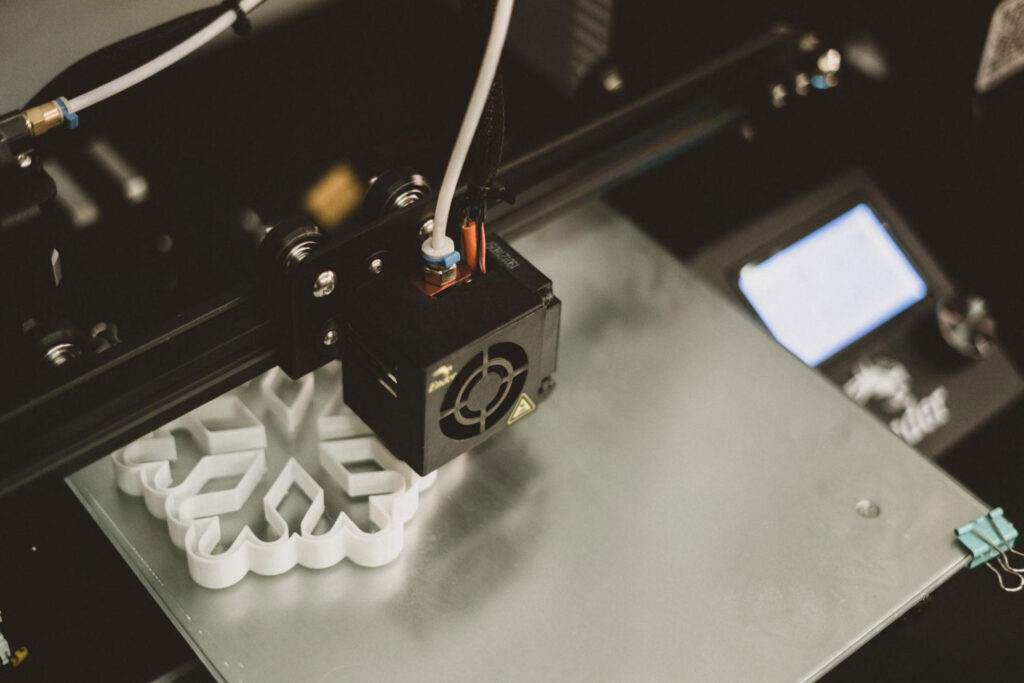

3D printing technology has emerged as a game-changing and revolutionary tool in the areas of medicine and healthcare delivery. It can also be used to increase the efficiency of drug development, accelerate time to market for complex medical devices and spare parts, eliminate some of the most tedious steps in manufacturing, and help jumpstart organ manufacturing once the biological components are ready.

3D printing in healthcare is increasingly deployed in both clinical and research-based healthcare activities to conduct a variety of medical advances. These can be used in the planning of various surgeries and procedures, or as patient-specific models for physicians or surgeons to use during an operation. They could also be used for a variety of other medical purposes, such as education or simply for explaining medical concepts to patients who may have difficulty visualizing their condition through traditional methods. And with that said, let’s thoroughly discuss some promising samples of how 3D printing can be used in healthcare.

1. Improved Surgical Instruments

As some of you may know, the field of medicine has evolved over the years in ways that were unimaginable according to even the latest technology. As a result, new surgical techniques and operations have been developed which are more efficient and do not use as many resources as before. For instance, 3D printing has been utilized to create surgical instruments, such as forceps, hemostats, scalpel handles, and clamps, which can be produced using 3D printers. One of the main benefits of 3D printing — aside from the traditional manufacturing methods to produce surgical instruments, is its cost-effectiveness, making surgical instruments more accessible.

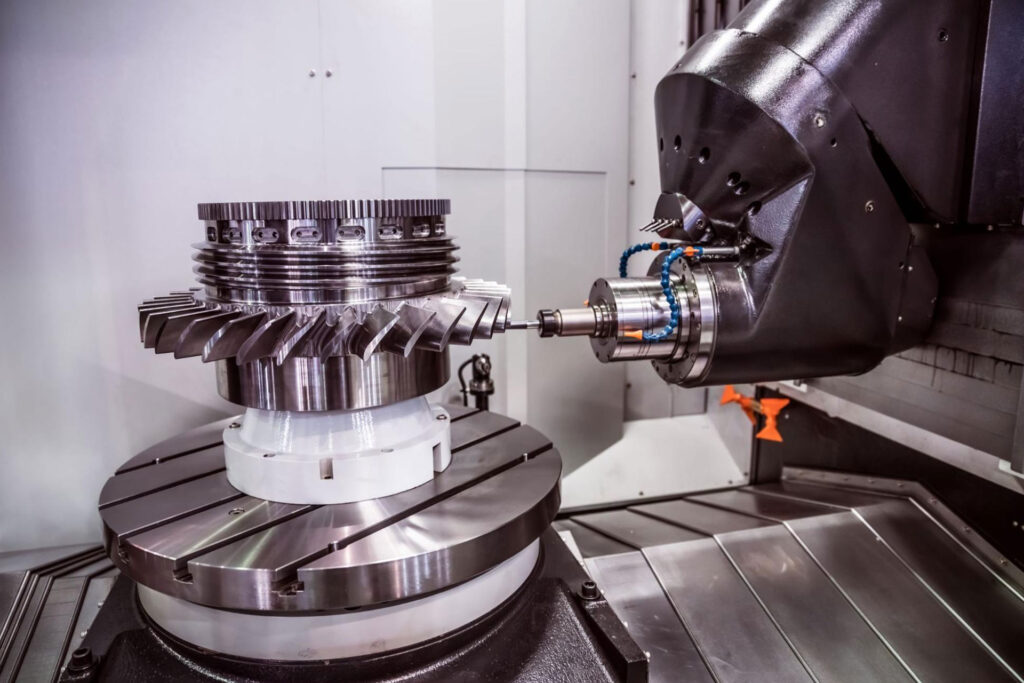

2. Creation of Medical Devices

Medical devices come in all shapes and sizes. Some have a simple design and are made of only one material while others can be quite complex and need to be composed of different materials. 3D printing has made a huge impact in producing medical devices or components, especially for complex designs that would be inefficient or impossible to manufacture with traditional processes. In some cases, doctors use 3D-printed replicas of their patients’ anatomy to plan surgeries or examine the impact of disease on critical body parts. Also, dentists can 3D-print molds and models that replicate a patient’s anatomy such as a bone structure.

While it may not replace X-rays or dental exams, doctors are finding that 3D printing can help speed up their work, make customized treatments possible with less equipment, and allow more effective integration of multiple physicians’ expertise. This can create more precise diagnoses, better surgical plans, and more accurate research results for patients.

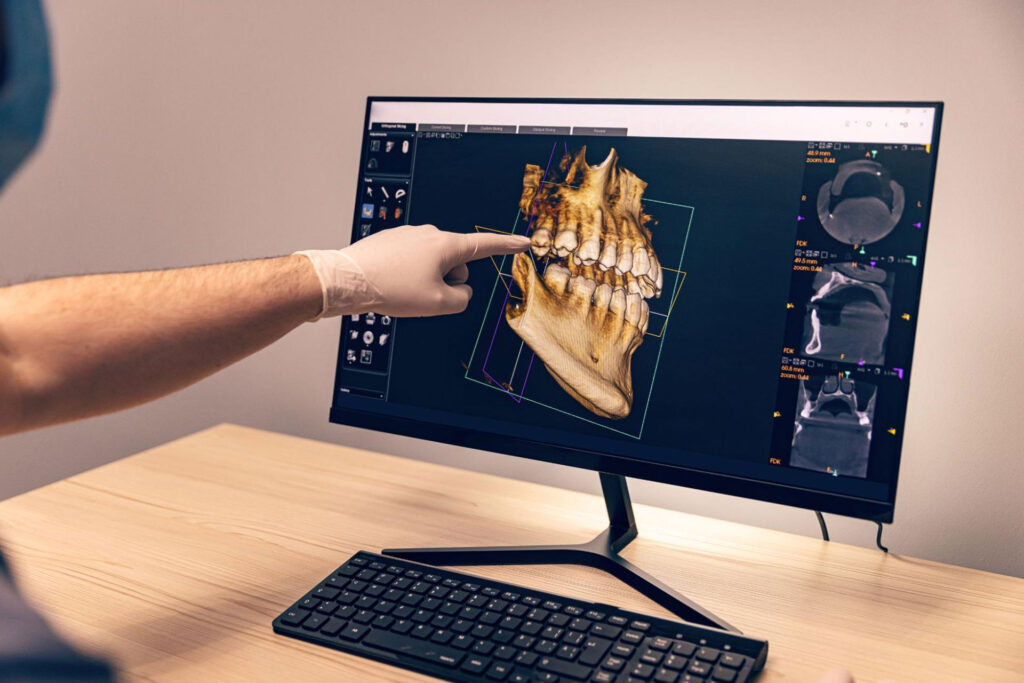

3. 3D Digital Dentistry

Each patient’s head is a different shape — and that doesn’t only mean from one side to the other, but also from back to front. Dental practices need CAD systems that can simulate these 3D anatomical differences for accurate planning, especially for patients who will wear oral prostheses or have dental procedures such as orthodontics, dentures, or surgery. Before the widespread use of digital workflows and 3D printing technology, designers had to rely on making physical models out of clay, metal or wax, which was a lengthy and labor-intensive process with only 50% accuracy. With a digital workflow including pre-operative planning (CAD/CAM), simulators, intraoperative imaging, and 3D printing technology, each dental product is precisely detailed to the specifications dictated by the patient’s anatomy.

4. Bioprinting

Bioprinting is a state-of-the-art technology that prints cells and biomolecules together with 3D printers that can create personalized human tissues which improves the current treatment options, reducing the demand for donor organs or animal models. Bioprinters are intended to replace or add body parts or help improve living conditions of those suffering from injuries. Bioprinted tissues can be used for drug testing, in transplantation medicine, tissue engineering, and regenerative medicine.

5. Affordable Custom Made Prosthetics

3D printing in the medical field can be used to produce prosthetic limbs that are customized to suit the wearer. Prosthetics have been around for quite some time; however, it was not until recently that there was a move towards more affordable, custom-made prosthetics. Custom-made prosthetics take great strides to ensure cost-effective and convenient options for patients seeking prosthetic limbs.

At this point, 3D printing in healthcare is still in its early days. The technology is improving all the time, but how long will it take before it becomes advanced enough to be a viable solution for both prosthetics and transplants? We do not know. But we’re sure that the manufacturers will continue to try to improve on what they have. And of course, there’s no guarantee that a suitable replacement body part will be created using 3D printing methods. It may just be that the patient needs to change as time goes by. Regardless of how things unfold, it will be exciting to see how 3D printing continues to change the way that we treat disease and injury in medicine.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!