3D Printing in the Energy Sector: A Guide

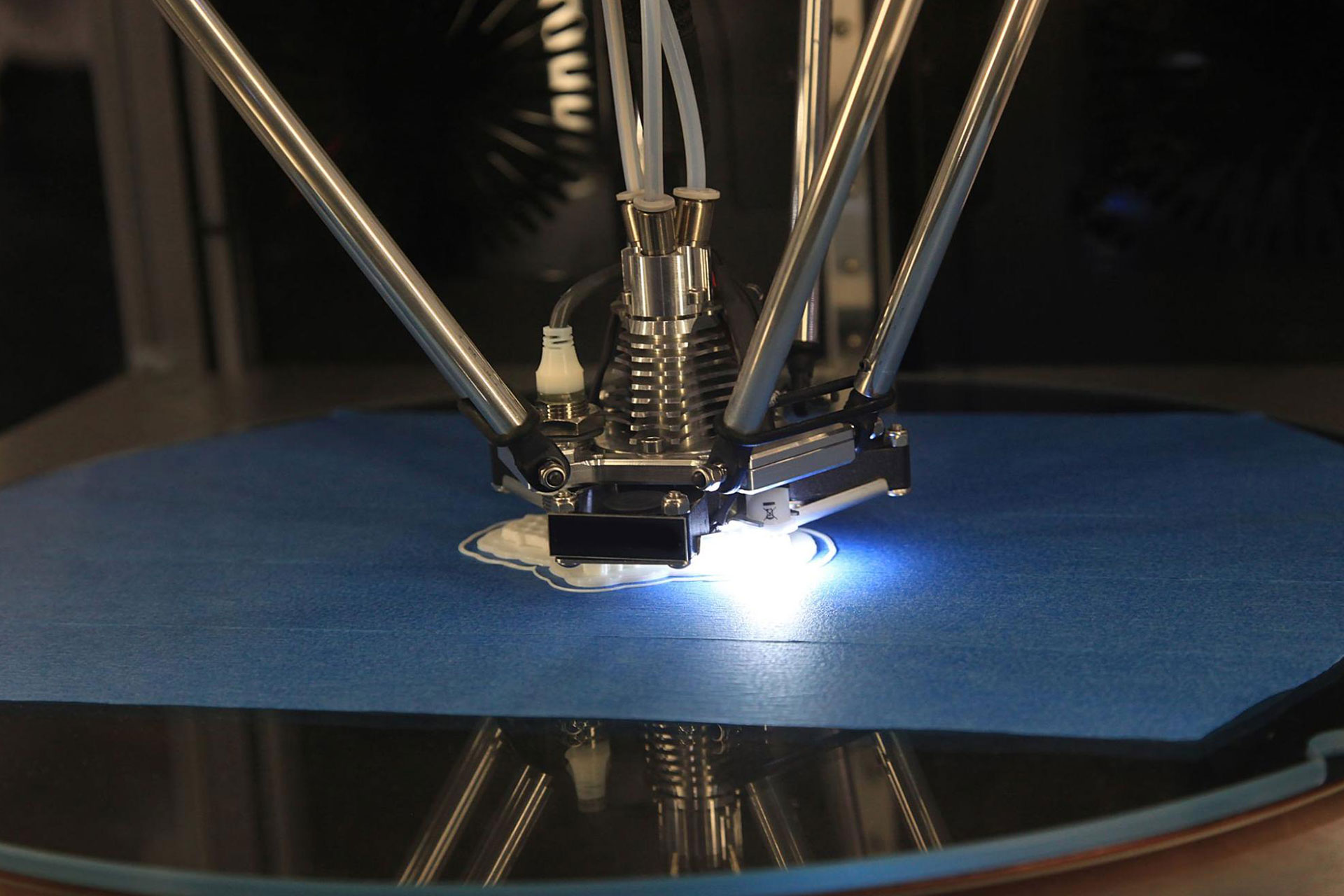

In recent years, 3D printing technology has been making waves across various industries, revolutionizing the way products are designed, prototyped, and manufactured. One sector that has been significantly impacted by this innovation is the energy sector. From renewable energy advancements to improving traditional energy infrastructure, 3D printing is playing a pivotal role in shaping the future of energy production and distribution. So in this guide, we will look into how 3D printing has been making positive effects in the energy sector, exploring its applications, benefits, and potential challenges.

1. Applications in Renewable Energy

Renewable energy sources like solar, wind, and hydropower are key players in the transition towards a more sustainable future. 3D printing technology is being harnessed to optimize the efficiency and effectiveness of renewable energy systems. For example:

Solar Energy

3D printing is enabling the creation of intricate and customized solar panel designs, enhancing energy capture and output. A 3D-printed solar panel is also easier to produce and is seen as a cheaper alternative, lessening the production time and cost.

Wind Energy

Turbine components and blades are being manufactured using 3D printing, allowing for more aerodynamic and lightweight designs, ultimately improving energy conversion.

Energy Storage

3D printing technology is playing a pivotal role in the development of innovative battery designs for renewable energy storage. By customizing the structure of battery electrodes and electrolytes, 3D printing can increase energy density, charge-discharge rates, and overall battery lifespan. This advancement is essential for enabling smoother integration of renewable energy sources into the grid.

2. Enhancing Traditional Energy Infrastructure

While 3D printing is widely associated with cutting-edge technologies, its impact goes beyond just futuristic applications. Traditional energy infrastructure, which includes fossil fuels and nuclear power, is also benefiting from the advancements offered by 3D printing.

Gas Turbines and Fossil Fuels

Advanced Components: 3D printing is being utilized to manufacture gas turbine components with complex designs that were once difficult or impossible to create using traditional manufacturing methods. The result is increased efficiency, reduced emissions, and improved performance of these turbines. Components like blades, combustion chambers, and nozzles are being optimized through 3D printing for better energy conversion and overall operational effectiveness.

Reduced Downtime: When parts of gas turbines or other fossil fuel-based equipment require replacement due to wear and tear, 3D printing offers a faster solution. Instead of waiting for lengthy lead times for traditional replacements, 3D printing allows for on-demand production of spare parts, minimizing downtime and ensuring continuous energy

Oil and Gas Industry

Rapid Prototyping: In the oil and gas sector, where equipment needs to withstand harsh conditions, 3D printing facilitates rapid prototyping of new tools and components. This accelerates the design and testing phases, enabling the development of more efficient and resilient equipment for exploration, drilling, and extraction processes.

Remote Locations: Many oil and gas operations take place in remote or challenging environments. 3D printing allows for on-site production of essential parts and tools, reducing the need for transportation and logistics, and increasing operational efficiency in challenging conditions.

Nuclear Energy

Enhanced Safety: Nuclear reactors require components that can withstand extreme conditions, such as high temperatures and radiation exposure. 3D printing enables the creation of complex and highly customized parts that meet these stringent requirements. This results in enhanced safety, reliability, and performance of nuclear power plants.

Reduced Lead Times: The production of components for nuclear reactors often involves lengthy lead times due to strict quality control and safety regulations. 3D printing can significantly reduce these lead times, enabling faster maintenance and replacement of critical reactor parts.

Benefits of 3D Printing in the Energy Sector

Rapid Prototyping

3D printing allows for quick and cost-effective prototyping of new energy technologies, facilitating faster innovation cycles.

Customization

The ability of 3D printing technology to create intricate and customized designs empowers energy companies to tailor solutions to specific needs, improving overall efficiency.

Reduced Environmental Impact

Through optimizing designs and using less material, 3D printing can lead to reduced waste and energy consumption in production.

Remote Manufacturing

3D printing enables on-site manufacturing in remote or challenging locations, reducing transportation costs and logistical complexities.

Challenges and Considerations

It’s important to consider that while 3D printing provides some benefits to the energy sector, there are also potential challenges that come with it.

Material Limitations

Not all materials are suitable for 3D printing, and finding the right materials with desired properties can be a challenge.

Quality Assurance

Ensuring consistent quality in 3D-printed components is crucial, especially in safety-critical applications like energy production.

Regulatory Complications

Meeting industry standards and regulatory requirements for 3D-printed energy components can be a complex process.

Initial Investment

Although 3D printing may demonstrate cost-effectiveness in the long run, the initial investment for equipment and training can be a challenge, making it an important matter to consider as well.

As technology continues to advance, the synergy between 3D printing and the energy sector is expected to reshape the industry’s landscape. Researchers and engineers are continuously exploring new materials, designs, and applications to drive innovation forward. Collaboration between academia, industry, and government bodies will also play a crucial role in unlocking the full potential of 3D printing in the energy sector.

Fusing 3D printing technology with the energy sector marks an exciting chapter in the journey towards a more sustainable and efficient energy future. From optimizing renewable energy systems to improving the reliability of traditional energy infrastructure, the possibilities are vast. As challenges are addressed and new breakthroughs emerge, 3D printing will undoubtedly continue to drive transformative changes, which will shape the energy industry for generations to come.

Looking for quality 3D printing in the Philippines? Contact us today to learn more about our products!