3D Printer vs. CNC Router: Which One Should You Use?

3D printing is a growing technology that has many advantages over other methods of manufacturing. However, it also has its drawbacks, including its lack of adaptability to mass production and the fact that it can’t be used for highly specific parts. For subtractive manufacturing methods, CNC routers are fast and versatile but can only be used for low-to-mid production. We’ll compare and contrast these two techniques to see how they stack up against each other.

3D Printer vs. CNC Router

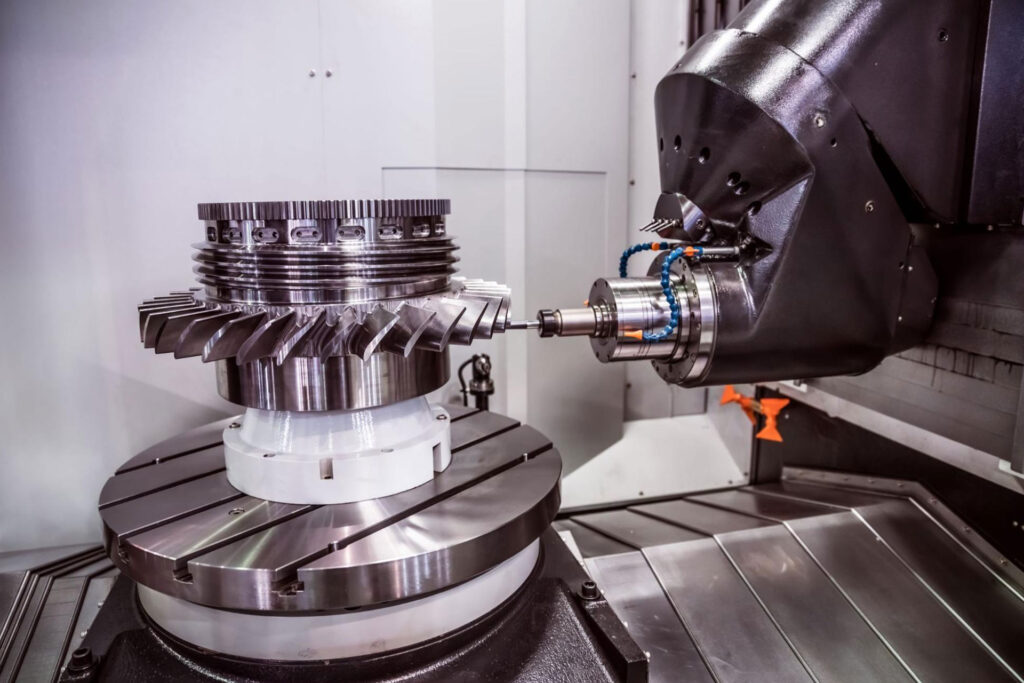

The differences between a CNC router and a 3D printer have to do with their methods. A CNC router uses tools that cut away at material to shape the piece, while a 3D printer builds up a finished product in layers. Another big difference is that a 3D printer is used for additive manufacturing, while a CNC router falls under subtractive manufacturing.

Materials

When it comes to the usage of different kinds of materials CNC uses a wide variety of resources to produce a designated product and these include ABS, Nylon (PA66), Polycarbonate (PC), Acrylic (PMMA), Polypropylene (PP), POM, and PEEK. While some common metals used in CNC are aluminum, stainless steel, magnesium alloy, zinc alloy, titanium, and brass these materials can create an effective prototype for machining.

3D printers, on the other hand, allows you to make prototypes out of thermoplastic photo-polymers like wax and calcinable resins, sand, ceramics, and even living materials. For metal printing, you can use aluminum, stainless steel, titanium, or Inconel. An important side note is that metal 3D printing is highly expensive because it requires industrial machines. There are also some materials such as superalloys or flexible materials that cannot be created with the use of subtractive methods such as the CNC, and 3D printing is usually used or rapid tooling technology.

User-Friendly

A CNC router is known to be more time-consuming than a 3D printer. This is because a CNC router involves preparing and cutting the material, installing it in the machine, and monitoring its progress until completion. With a 3D printer on the other hand, once the file is prepared, you simply choose the part of orientation and fill it. After that, it’s just a matter of pressing ‘print.’ Further post-processing depends on the product and technology at hand.

In contrast to a CNC router, a 3D printer is less labor-intensive. A skilled operator selects the appropriate tool and sets rotation speeds, the cutting path, and repositions the material being used. The post-processing steps are also time-consuming.

Size Limitations and Geometric Structures

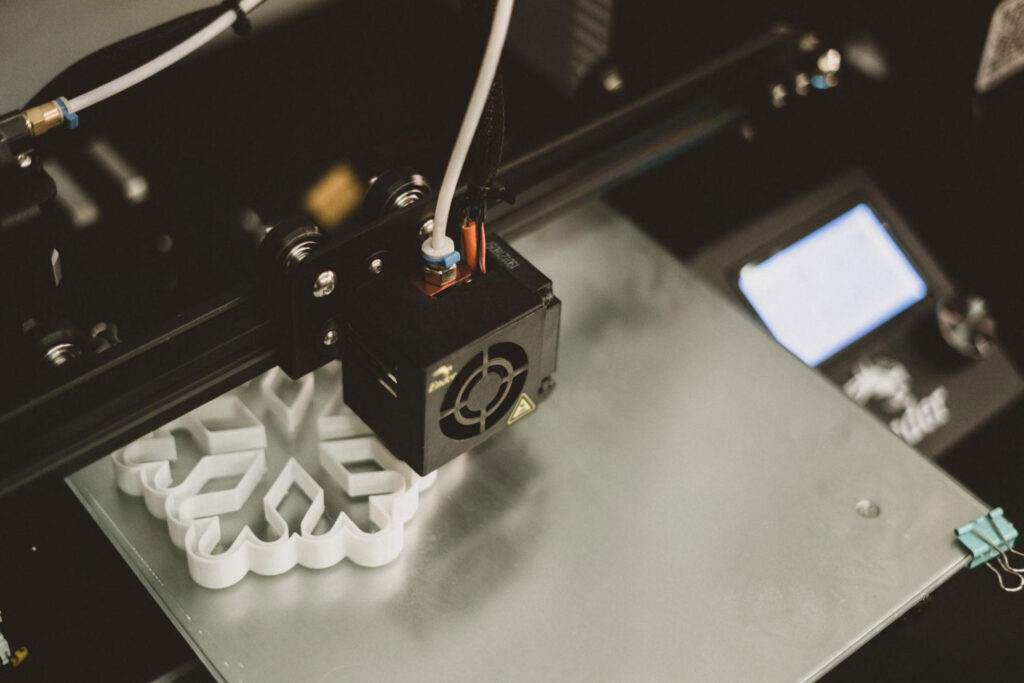

Although a 3D printer involves processes like SLS and DMLS that have bigger build volumes than technologies like FDM, they cannot compete with CNC routers when it comes to the size of parts they can produce. But when it comes to geometric structures, 3D printers can create complex geometries that make traditional manufacturing methods seem primitive.

The stacking of complex shapes on top of each other is something that can solve intricate problems in advanced manufacturing. Although it might sound simple, there are many 3D printing technologies capable of performing the process known as geometric complexities.

Geometric complexity is a way of describing the surface detail on a part using algorithms and software. There are many ways to create complex surfaces such as complex curves, surface detail, and more. Geometric complexities can be generated by 2D and 3D meshes and even parametric modeling techniques for computer-aided design (CAD). These complexities can provide exciting designs that have endless possibilities.

Costs

Both a 3D printer and a CNC router are used to create end-use parts for a variety of industries, including automotive, aerospace, and medical. Depending on the quantity needed, the costs associated with these processes vary. For higher quantities, a CNC router tends to be more cost-effective; while in smaller quantities, a 3D printer is typically less expensive and faster.

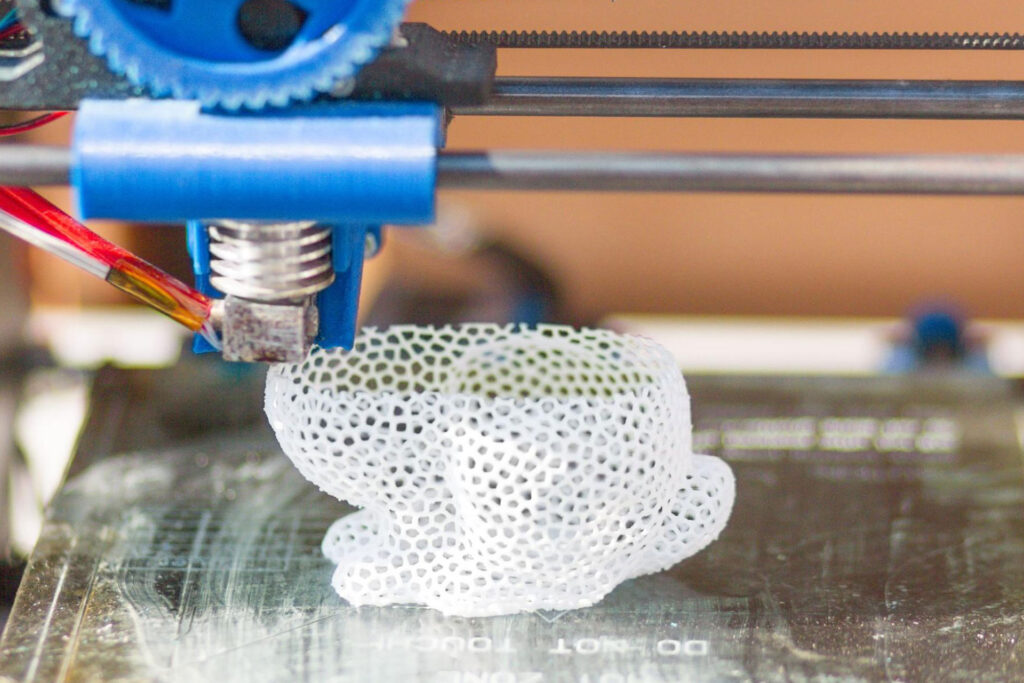

Waste

Since additive manufacturing involves building an object from the bottom up, there is no waste except for support. The unused material required by competing processes is often discarded. This makes 3D printing more sustainable and environmentally responsible. A CNC router, however, involves cutting material away from the original block, which means there is always going to be a mess to be cleaned up afterward.

Conclusion

While both of these technologies have been used for decades, they are only now beginning to make a name for themselves in mainstream manufacturing. The 3D printer has proven to be more versatile for certain applications, allowing unconventional designs and concepts to become reality by simply “printing” them out. Simple geometries are fairly easily engineered with a CNC router, while a 3D printer is better suited for producing complex structures or workflows that require less post-production assembly.

Ultimately, there’s no one best way to manufacture a design. Whether you decide to make something using a CNC router or a 3D printer will depend on the material, shape, volume, and budget.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!