SLA vs. FDM 3D Printing: Which is the Better Option?

The world of 3D printing is constantly evolving, and with so many different options available, it can be difficult to decide which technology is the best fit for your project. With that, we will be taking a look at the SLA and FDM 3D printing technologies and compare their strengths and weaknesses.

Related: What are the Different Types of 3D Printing Methods?

Keep in mind that while these methods both produce three-dimensional objects, they do so in very different ways. By the end of this article, we hope that you’ll have a better understanding of which technology is more suitable for your project requirements.

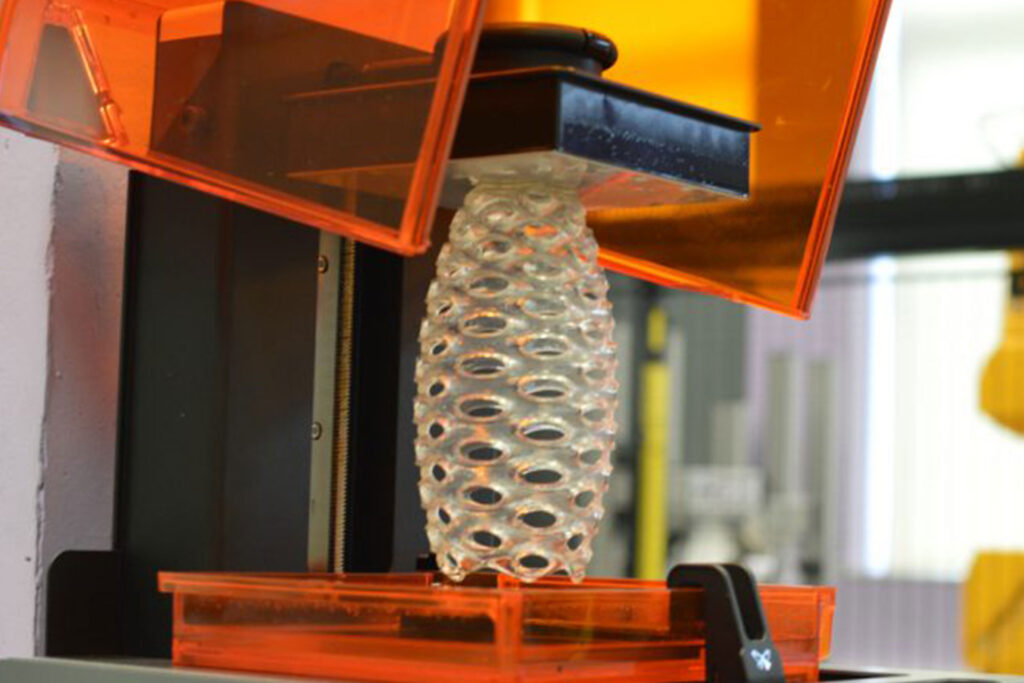

What is SLA (Stereolithography) 3D Printing?

Stereolithography, better known as SLA 3D printing technology, uses a liquid resin that is cured with a laser to create a solid object. The resin is placed in a tank, and the laser beam traces the shape of the object onto the surface of the resin, causing it to solidify. The process is then repeated layer by layer until the final object is complete.

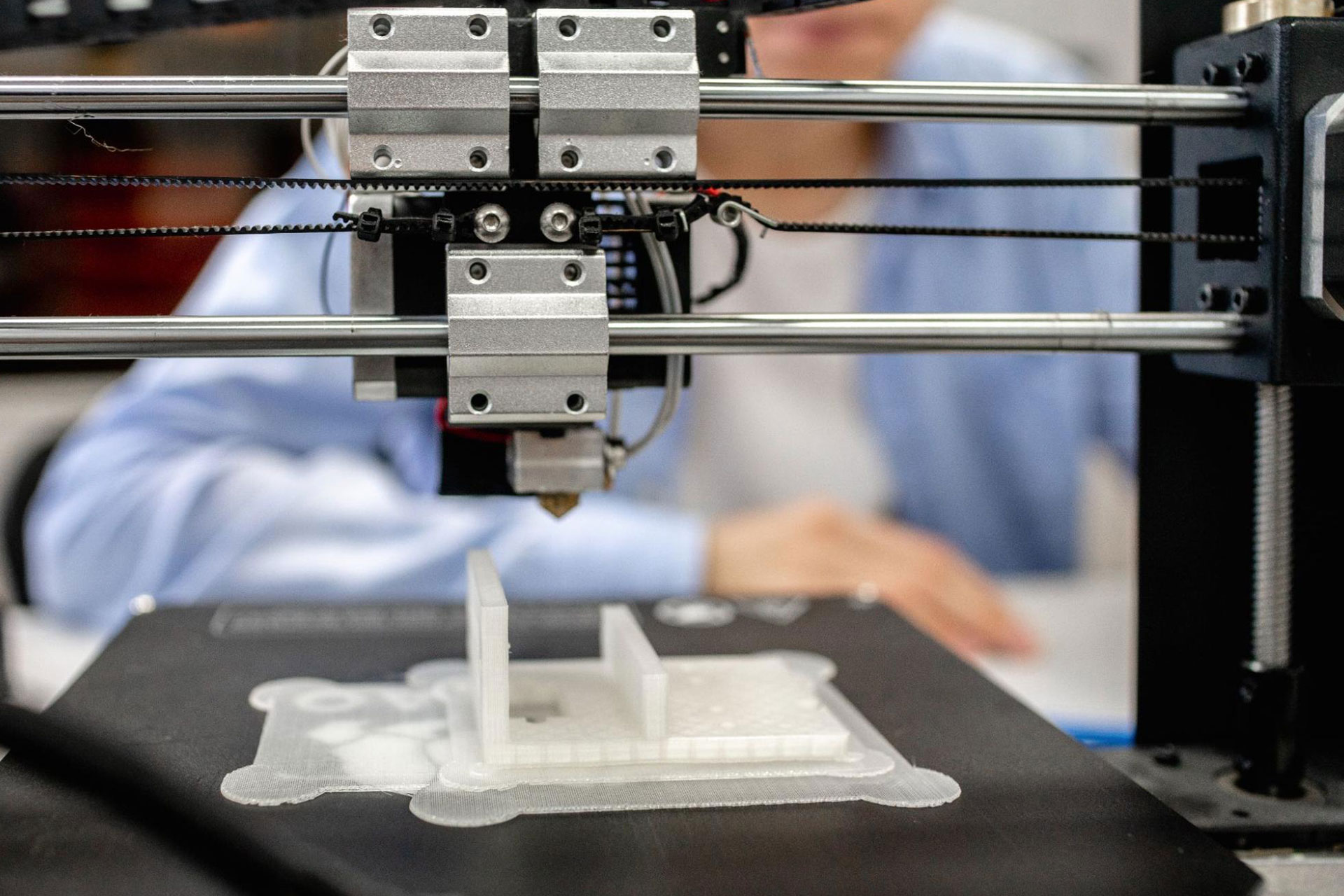

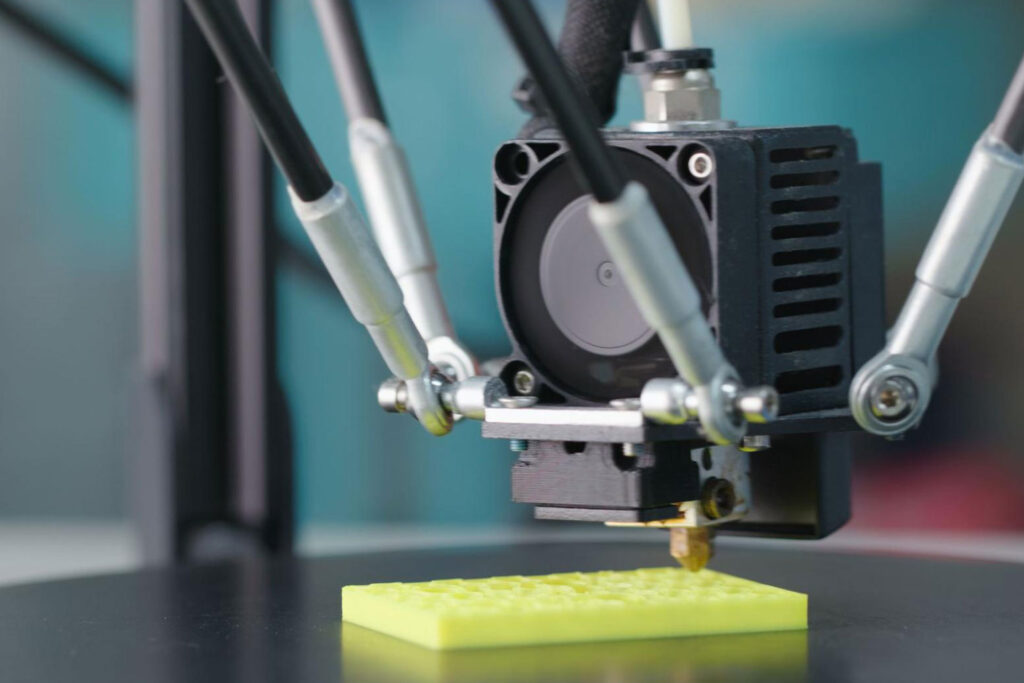

What is FDM (Fused Deposition Modeling) 3D Printing?

FDM or Fused Deposition Modeling 3D printing, on the other hand, uses a thermoplastic filament that is melted and extruded through a nozzle to create the object. The filament is fed through the printer, and the nozzle moves back and forth, depositing the melted plastic in a precise pattern to build up the object layer by layer.

Now that we have a basic understanding of how these two technologies work, let’s compare them based on a few factors.

Comparison

Print Quality

In terms of print quality, SLA technology tends to produce higher quality prints than FDM technology. SLA printers are usually slower compared to FDM printers, but they are capable of producing very detailed and intricate designs with smooth surfaces, sharp corners, and fine details. FDM printers, on the contrary, can produce rougher surfaces and have visible layer lines.

For large and simple parts, FDM is a viable option. But if you will mostly be printing complex parts, SLA may be a better choice since it can produce more accurate results.

Speed

If you’re particular with speed and you want faster outcomes, FDM technology may be a good option for you because it is generally faster than SLA technology. FDM printers can print larger objects faster than SLA printers, and the printing process is generally more straightforward.

Cost

When it comes to cost, FDM technology is more affordable than SLA technology. FDM printers and filament are widely available and relatively inexpensive. However, with SLA printers, they are normally more expensive and the resin used in this method may also be a bit costly, making it a challenge for those who are trying to watch their budget.

Material Options

FDM technology offers a wider range of materials to choose from compared to SLA technology. This is because FDM printers can use a variety of thermoplastics, including ABS, PLA, PETG, Nylon, and TPU. While SLA printers are limited to using photopolymers (resins), which are specifically designed for the technology.

Related: 10 Common Materials Used in 3D Printing

Both SLA and FDM 3D printing technologies have their advantages and disadvantages — and it doesn’t mean that one method is superior to the other. If you prioritize print quality over speed and cost, then SLA technology is the better option. But if you want to focus on speed and cost over print quality, then FDM technology is the finer choice. Ultimately, the choice between the two technologies will depend on your specific needs and budget.

Looking for quality 3D printing in the Philippines? Contact us today to know more about our products!