CNC Milling: Must-Know Advantages and Disadvantages

CNC machining is capable of doing a plethora of fabrication and CNC milling operations, hence why it is widely used in various industries for manufacturing. With CNC milling being a versatile process, it can be very useful in creating prototypes, fabricating mechanical parts, as well as in other applications. But despite its known remarkable advantages, just like any other manufacturing process, CNC milling also has disadvantages that come with it.

In this article, we will be underscoring both the advantages and disadvantages of CNC milling, so keep scrolling through to know more:

What is CNC Milling?

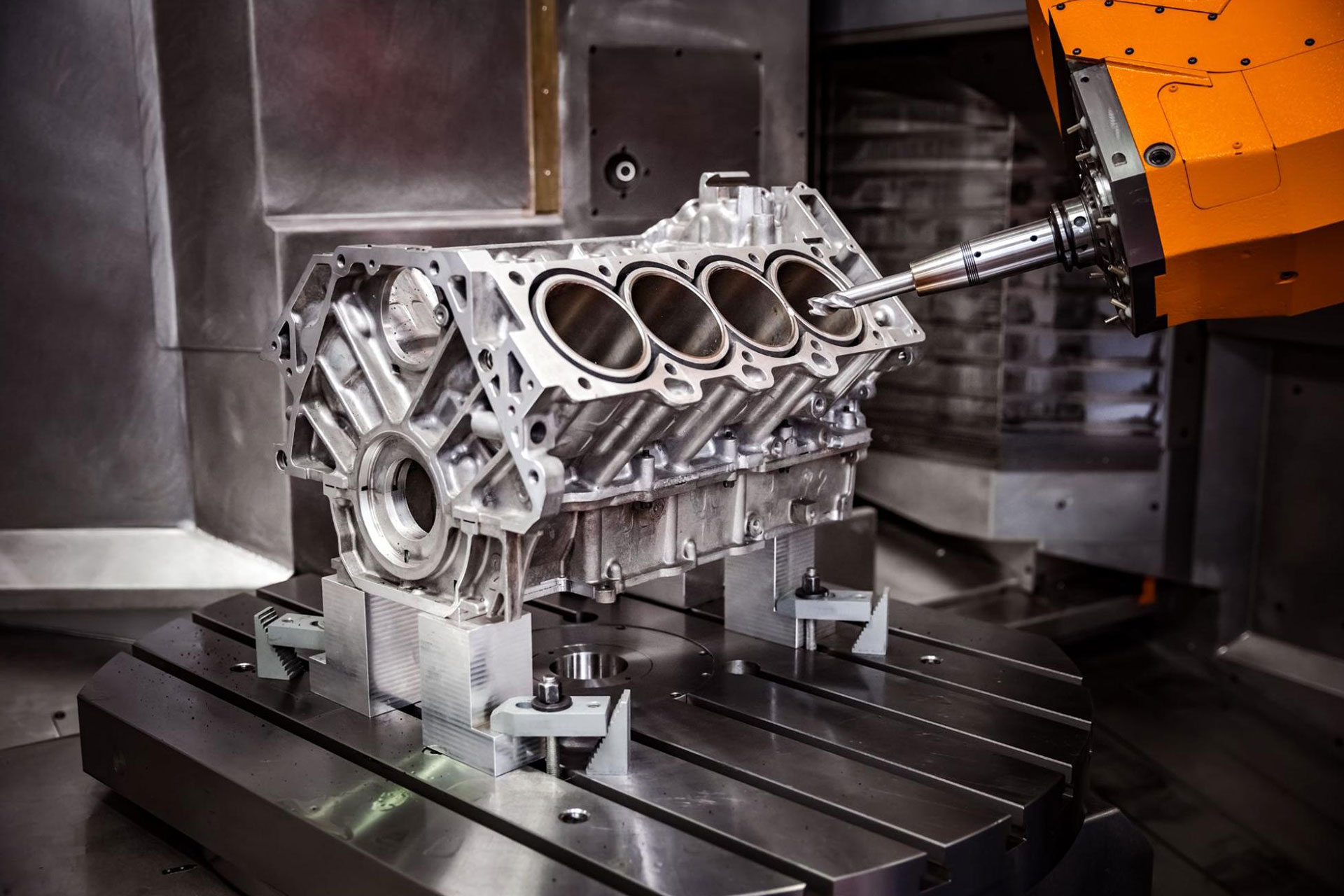

CNC (Computer Numerical Control) milling is a manufacturing process that is used to cut materials to produce a finished product or design. Unlike 3D printing which is an additive manufacturing process, CNC milling is a subtractive manufacturing process that ‘subtracts’ material from solid blocks of raw materials. This process involves the use of milling machines to cut, drill, or grind materials and carve them into a desired 3D geometrical shape.

Related: A Guide to What CNC Milling is All About

Advantages

1. Affordable

Compared to other modern or present-day manufacturing processes, CNC milling is the most affordable and cost-effective professional CNC machine that’s available in the market, making it ideal for businesses who mostly depend on third-party manufacturers.

2. High-Precision

CNC milling machines are known for being highly precise in creating and fabricating parts. This is mainly because CNC mills entirely depend on computer instructions, and doesn’t involve much human labor — thus, leaving zero room for errors done by manually operated machines.

3. Supports a Wide Array of Materials

Metals are the most common materials used in CNC milling machines, but you can also make use of different types of wood (hardwood, plywood, softwood) and plastics (PC, PP, PMMA, POM).

4. Reliable Speed

CNC mills are not only highly precise, but they are also fast — meaning, you can have your parts done in just a matter of hours, and you wouldn’t have to wait for days for the parts to be finished.

On top of that, CNC mills can run 24/7 without tiring (and will only need to be turned off for occasional maintenance), so it helps operators to be more productive, making the production process more efficient by reducing production time and costs.

5. Great Capabilities to Produce Complex Parts

Advanced manufacturing settings and techniques come with CNC milling machines, enabling them to produce and fabricate even the most complex parts.

6. Depends Less on Human or Manual Labor

CNC machines can be supervised by one person, and can be left to work by themselves. It relies less on manual or human labor, which means it is less likely to come across human errors.

Disadvantages

1. Not Enough Qualified Technicians

Despite CNC milling machines being automated, it will still need highly skilled and qualified technicians or engineers to operate and supervise it. However, there are not enough qualified CNC milling operators, so there may also be a lot of low-quality machined parts.

2. Tends to Leave More Waste

Since CNC milling starts with a block of raw materials and afterwards, cuts or removes a portion of the material to form the desired shape, you can expect that it will leave more waste compared to 3D printing which is an additive manufacturing process.

3. More Expensive Than Manually Operated Machines

CNC milling machines have more advanced settings and capabilities compared to the conventional or manually operated machines, so it’s a no-brainer that it will be more expensive. It only becomes a disadvantage if you compare the price with manually operated machines, nevertheless, it’s still affordable.

4. Less Labor Involved Would Mean Unemployment for Some

Less labor needed to operate automated machines like the CNC mills would mean providing less opportunity for employment to other people.

CNC milling machines are just like any other technology advancements that come with their own set of pros and cons. Looking at the advantages and disadvantages will help you weigh your options, however, at the end of the day, it all depends on your needs, preferences, and budget.

Looking for quality CNC milling in the Philippines? Contact us today to know more about our products!